Get Famous Branded Quality at Factory Cost

Pls inquire to sales@danddhardware.com

\\: +86 139 2903 7292

Author: Site Editor Publish Time: 2025-11-17 Origin: Site

A hydraulic door closer is a common sight in commercial buildings, offices, and even some homes. This simple but effective device ensures a door closes automatically and in a controlled manner, enhancing safety, security, and energy efficiency. However, when it’s not working correctly—slamming shut, closing too slowly, or not latching at all—it can become a nuisance or even a hazard.

Learning how to adjust a hydraulic door closer can save you the time and expense of calling a professional. With just a few basic tools and a bit of patience, you can fine-tune its performance to meet your needs. This guide will walk you through everything you need to know, from understanding how the closer works to making precise adjustments for a perfectly functioning door.

A hydraulic door closer is a mechanical device that uses fluid pressure to control the swinging motion of a door. It consists of a metal housing containing a spring and a hydraulic fluid-filled chamber. When the door is opened, the spring is compressed, storing energy. As the door closes, this energy is released, and the hydraulic fluid moves through a series of valves and channels within the housing.

By adjusting these valves, you can control the speed at which the fluid flows, which in turn regulates the door's closing speed. Most modern closers are highly adjustable, allowing you to fine-tune different phases of the closing cycle for smooth, safe operation.

D&D Hydraulic Door Closer :

CE Door Closer - BS EN1154 500,000 cycles test, EN1634 Fire Rated 120/180mins, EN1670 Corrosion Resistance 96 hours.

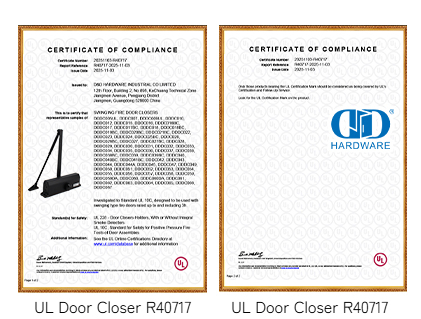

UL Door Closer - UL Listed, UL 10C Fire Rated 3 Hours, UL File No.R40717

Before you start making adjustments, it's helpful to familiarize yourself with the main parts of a typical hydraulic door closer:

· Main Body/Housing: This is the main component that mounts to the door or frame and contains the spring and hydraulic mechanism.

· Arm Assembly: This connects the main body to the door or frame and consists of two parts: the main arm and the forearm. These arms work together to transfer the closing force.

· Adjustment Screws/Valves: These small screws, usually located on the side or end of the closer body, are used to control the different aspects of the closing cycle. They are typically labeled or color-coded.

Understanding the common issues can help you diagnose the problem with your door and determine which adjustments are needed.

· Door Slams Shut: The door closes too quickly and with excessive force. This is not only loud and disruptive but can also be dangerous and cause damage to the door and frame.

· Door Closes Too Slowly: The door takes a long time to close, posing a security risk and reducing energy efficiency by allowing conditioned air to escape.

· Door Doesn't Latch: The door closes almost completely but lacks the final push needed to engage the latch, leaving it slightly ajar.

· Door is Hard to Open: The spring tension might be set too high, making the door difficult for some people, particularly children or the elderly, to open. This can also be an accessibility issue.

· Leaking Fluid: If you notice oil or hydraulic fluid leaking from the closer body, it's a sign that the internal seals have failed. In this case, adjustment won't solve the problem, and the entire unit will need to be replaced.

Adjusting a hydraulic door closer involves fine-tuning several screws that control different phases of the closing cycle. Most closers have a diagram printed on the body or cover that labels these screws. If not, you may need to do a little trial and error, but the functions are generally standard.

Important Note: Make small adjustments at a time—a quarter-turn is often enough to see a significant change. Over-loosening a valve screw can cause it to fall out, leading to a loss of hydraulic fluid and a broken closer.

Most hydraulic door closers have a plastic or metal cover for aesthetic purposes. This cover usually snaps on or is held in place by a couple of screws. Gently pull it off or unscrew it to expose the main body of the closer and the adjustment screws. Be careful not to use excessive force, as you don't want to crack the cover.

Once the cover is off, you will see a series of small screws on the side or end of the closer body. These are the valves that control the hydraulic fluid flow. While the exact labeling can vary between manufacturers, you will typically find screws for the following functions:

· Sweep Speed (or Closing Speed): This is the main adjustment and controls the speed of the door from the fully open position until it's about 6-12 inches from the frame. It's often labeled "S" or "C."

· Latch Speed (or Latching Speed): This screw controls the final few inches of the door's travel, ensuring it latches securely into the frame without slamming. It's often labeled "L."

· Backcheck (Optional): Some closers have a backcheck feature, labeled "BC," which provides resistance when the door is opened forcefully past a certain point (usually around 75 degrees). This prevents the door from being thrown open and hitting a wall.

Start by adjusting the main closing speed.

1.Open the door fully and let it close on its own. Observe the speed.

2.If the door closes too quickly, turn the sweep speed screw clockwise in small increments (quarter-turns). This restricts the flow of hydraulic fluid, slowing the door down.

3.If the door closes too slowly, turn the sweep speed screw counter-clockwise in small increments. This allows more fluid to flow, speeding up the door.

4.Test the door after each adjustment until you are satisfied with the speed. A good rule of thumb is for the door to close from a 90-degree open position in about 5-7 seconds.

Next, fine-tune the latching speed. This is the critical phase that ensures the door overcomes the resistance of the latch bolt and closes securely.

1.Watch the door as it enters the final 6-12 inches of its swing.

2.If the door slams shut, turn the latch speed screw clockwise to slow it down.

3.If the door doesn't have enough force to latch properly, turn the latch speed screw counter-clockwise to give it a bit more speed in the final moments.

4.Test the door several times to ensure it latches firmly but gently every time. You should hear a confident "click" as the latch engages.

If your hydraulic door closer has a backcheck feature and you feel it needs adjustment:

1.Open the door with more force than usual.

2.If there's too much resistance, making it hard to open the door, turn the backcheck screw counter-clockwise to decrease the cushioning effect.

3.If the door flies open and hits the stop or wall too hard, turn the backcheck screw clockwise to increase the resistance.

4.Test again until you find a balance that protects the door and wall without making it difficult to open.

Once all adjustments are complete and you are happy with the door's performance, snap or screw the cover back into place.

Adjusting a hydraulic door closer is a simple yet effective way to improve the safety, security, and functionality of your doors. By following these steps and making small, careful adjustments, you can ensure your doors operate smoothly for years to come.

If you find that you cannot adjust the closer to your satisfaction, or if you notice any oil leaking from the unit, it's a sign that the closer's seals have failed. In this case, the entire unit will need to be replaced. But for most common issues, a few turns of a screwdriver are all it takes to get things back in perfect working order.

Click here for additional details on door closers.

Now contact us.

Contact information for David Jian

Contact number: 0086-139 2903 7292

Email address: sales@danddhardware.com