Get Famous Branded Quality at Factory Cost

Pls inquire to sales@danddhardware.com

\\: +86 139 2903 7292

Installing a door closer might seem daunting, but with the right tools and guidance, it's a manageable DIY project that can enhance your home's security and energy efficiency. Whether you're dealing with a heavy front door that won't stay shut or looking to comply with accessibility requirements, a properly installed door closer ensures your door closes automatically and securely every time.

This comprehensive guide will walk you through the entire installation process, from selecting the right door closer to making final adjustments. By the end, you'll have the confidence and knowledge to tackle this project successfully, saving money on professional installation while gaining a valuable new skill.

D&D Adjustable Door Closer :

CE Door Closer - BS EN1154 500,000 cycles test, EN1634 Fire Rated 120/180mins, EN1670 Corrosion Resistance 96 hours.

UL Door Closer - UL Listed, UL 10C Fire Rated 3 Hours, UL File No.R40717

A door closer is a mechanical device that automatically closes a door after it has been opened. These devices use hydraulic or pneumatic mechanisms to control the closing speed and force, ensuring doors close gently but securely.

Door closers offer several advantages for homeowners. They improve energy efficiency by preventing heated or cooled air from escaping, enhance security by ensuring doors don't accidentally remain open, and provide convenience for people carrying items or those with mobility challenges. Additionally, many building codes require door closers on fire doors and accessibility entrances.

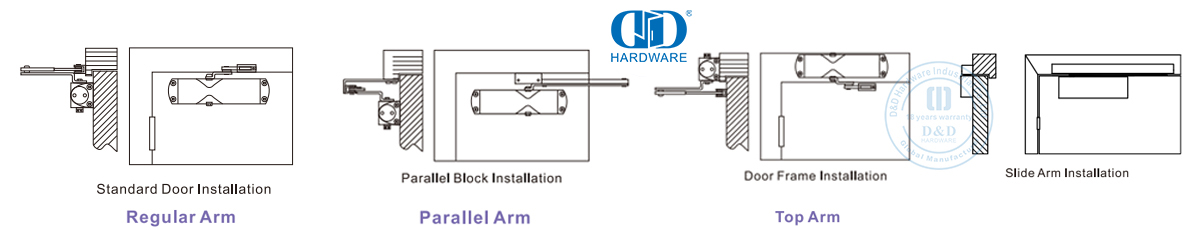

Before starting your installation, you'll need to choose the right type of door closer. Surface-mounted closers attach to the door and frame surface, making them the most common choice for DIY installations. Concealed closers hide within the door or frame but require professional installation. Overhead closers mount above the door, while floor-spring closers install in the floor beneath the door.

Gathering the proper tools beforehand will make your door closer installation much smoother. You'll need a power drill with various drill bits, a screwdriver set, a measuring tape, a pencil for marking, a level to ensure proper alignment, and safety glasses for protection.

The materials list includes your chosen door closer (sized appropriately for your door's weight and width), the mounting screws typically included with the closer, wall anchors if needed for hollow doors or weak frame materials, and possibly wood filler if you need to fill any existing holes.

When selecting a door closer, pay attention to the size rating. Door closers are rated by size numbers (1 through 6) that correspond to different door weights and widths. A size 3 closer works for most residential doors, while heavier commercial doors might require size 4 or 5 closers.

Start by carefully examining your door and frame to determine the best mounting location. Most door closers can be installed on either the pull side (where you pull the door open) or the push side (where you push the door open). The pull side installation is more common and typically easier for beginners.

Measure your door's weight, width, and thickness to confirm your door closer selection. Check that the door swings freely and the hinges are in good condition, as a door closer will put additional stress on the hardware. If your door sticks or sags, address these issues before installing the closer.

Clean the mounting surfaces thoroughly to ensure good adhesion and mark any existing screw holes that might interfere with your installation. Take photos of your current door setup for reference, especially if you're replacing an existing closer.

Begin by positioning the door closer body on the door according to the manufacturer's template. Most closers come with a paper template that shows exactly where to drill holes and mount the device. Tape this template securely to your door, ensuring it's level and properly aligned.

Mark all screw holes with a pencil, then remove the template and drill pilot holes. The pilot hole size should be slightly smaller than your mounting screws to ensure a tight fit. For solid wood doors, drill straight through. For hollow doors, you may need to use appropriate anchors or toggle bolts.

Mount the closer body using the provided screws, ensuring it sits flush against the door surface. Don't fully tighten the screws yet – you'll want to make minor adjustments after installing the arm. Check that the closer body is level and properly aligned with your door's swing direction.

The mounting bracket typically attaches to the door frame, though some installations may require it to mount on the wall above the door. Use your template to mark the bracket position, ensuring it aligns properly with the closer body when the door is closed.

Drill pilot holes for the bracket mounting screws. If you're mounting into drywall, use appropriate anchors. For masonry or concrete frames, you'll need masonry screws or anchors. Attach the bracket securely, checking that it's level and properly positioned.

Connect the closer arm between the closer body and mounting bracket. Most modern closers use a pin connection system that allows for easy installation and adjustment. Insert the pins and secure them according to the manufacturer's instructions. The arm should move smoothly throughout the door's full range of motion.

Once your door closer is physically installed, you'll need to adjust its operation to suit your specific door and preferences. Most closers have multiple adjustment valves that control different aspects of the closing cycle.

The sweep speed valve controls how fast the door closes from the fully open position to about 15 degrees from closed. Turn this valve clockwise to slow the closing speed or counterclockwise to increase it. Start with small adjustments – typically no more than a quarter turn at a time.

The latch speed valve controls the final closing speed from about 15 degrees to fully closed. This should be faster than the sweep speed to ensure the door latches properly, but not so fast that it slams. Again, make small adjustments and test the door operation after each change.

Some closers also have a backcheck valve that controls how much the door resists when opened beyond 90 degrees. This prevents the door from slamming into walls or adjacent surfaces. Adjust this feature if your door tends to swing too widely when opened.

After making your initial adjustments, test the door closer thoroughly. Open the door to various positions and release it, observing how it closes. The door should close smoothly and latch securely without slamming or stopping short of the latch.

Check the closing action from different opening angles. A properly adjusted door closer will close consistently whether opened 45 degrees or 90 degrees. If the door stops closing at any point, you may need to increase the closing force or check for obstructions.

Test the door closer under different conditions. Temperature changes can affect hydraulic closers, so check operation during different weather if possible. Make sure the closer doesn't interfere with normal door operation and that all family members can open the door comfortably.

If your door won't stay open when you want it to, check if your closer has a hold-open feature. Some closers can be set to hold open at 90 degrees or other angles. If this feature isn't working, verify that it's properly engaged according to the manufacturer's instructions.

When a door closes too slowly or too quickly, return to the adjustment valves. Remember that sweep speed and latch speed are controlled separately, so you may need to adjust both to achieve the desired closing action. Always make small adjustments and test thoroughly.

If the door doesn't close completely or bounces off the frame, check that the latch speed isn't too fast and that the closing force is adequate. Also verify that the door and frame are properly aligned and that the strike plate is correctly positioned.

Regular maintenance will keep your door closer operating smoothly for years. Check the mounting screws periodically to ensure they remain tight, as the constant opening and closing can gradually loosen hardware.

Clean the closer body and arm regularly to prevent dirt and debris from affecting operation. Use a damp cloth and mild detergent, avoiding harsh chemicals that might damage seals or finishes.

Lubricate moving parts annually with the manufacturer's recommended lubricant. This typically involves adding a few drops of hydraulic fluid to designated ports. Never use general-purpose oils or lubricants unless specifically recommended.

Installing a door closer successfully requires attention to detail and patience. Take time to read the manufacturer's instructions completely before starting, as different brands may have specific requirements or recommendations.

Double-check all measurements and alignments before drilling holes, as mistakes can be difficult and expensive to correct. When in doubt, make test fits and adjustments before permanently mounting components.

Consider the door's intended use when making adjustments. A front door may need different settings than an interior door, and doors used by elderly or disabled individuals may require gentler closing actions.

Your properly installed door closer will provide years of reliable service, improving your home's security, energy efficiency, and convenience. With the skills you've gained from this project, you'll be well-equipped to handle similar installations or maintenance tasks in the future.

Click here for additional details on door closers.

Now contact us.

Contact information for David Jian

Contact number: 0086-139 2903 7292

Email address: sales@danddhardware.com