Get Famous Branded Quality at Factory Cost

Pls inquire to sales@danddhardware.com

\\: +86 139 2903 7292

Author: Site Editor Publish Time: 2025-11-05 Origin: Site

A hydraulic door closer is one of those unsung heroes of home and office maintenance. Operating silently in the background, it ensures doors close securely, manage temperature flow, provide privacy, and enhance security. But when it malfunctions—whether the door is slamming shut, not latching, or closing too slowly—it becomes a source of constant frustration.

Before you call a handyman, know that most issues with a hydraulic door closer can be resolved in minutes with a simple adjustment. This comprehensive guide will walk you through the process, explaining the different adjustment valves and providing practical solutions for common problems.

While models vary, most standard hydraulic door closers share a common design. The hydraulic fluid inside a cylinder is controlled by a series of valves and springs, which you can adjust to change the door's speed and force.

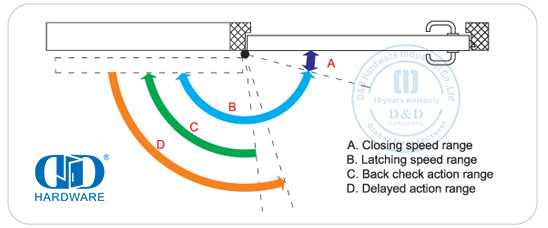

The two primary adjustment valves you’ll be working with are:

1.Swing Speed (Main Speed): This valve controls the door's speed over the majority of its swing, from the fully open position to about 15 degrees from the closed position.

2.Latch Speed (Final Closing Speed): This valve regulates the speed for the last few inches of the door's travel, ensuring it closes gently and securely into the latch without slamming.

Many modern door closers also feature a third adjustment:

3.Backcheck: This setting controls the door's speed when it is opened forcefully. It acts as a "buffer," preventing the door from swinging open too hard and damaging the door, wall, or the closer itself.

Adjusting a hydraulic door closer is a straightforward process. Always prioritize safety and make small, incremental changes.

Tools You’ll Need:

· A screwdriver (usually a flat-head or Phillips, depending on your model)

· A stepladder (if needed for overhead closers)

· A cloth for cleaning

Step 1: Identify the Adjustment ValvesLocate the two (or three) adjustment valves on the body of the closer. They are typically found on the end of the cylinder or along the side and are marked with labels like "S" and "L" (for Swing and Latch) or with directional arrows. If you no longer have the manual, a quick online search of your closer's brand and model can provide a diagram.

Step 2: The Golden Rule: Turn in Small IncrementsThis is the most critical step. The adjustment screws are very sensitive. Always turn the screws a quarter-turn or an eighth-turn at a time. Mark the screw's starting position with a marker if you're worried about losing your place. Making large turns can lead to over-adjustment, making the door inoperable or causing internal damage.

Step 3: Test the Door After Every AdjustmentAfter each small turn of a valve, open the door fully and let it close on its own. Observe the change in behavior. This methodical approach helps you pinpoint the perfect setting without guesswork.

Here’s how to use the adjustment valves to solve specific issues:

Problem 1: The Door Slams Shut

· Cause: The latch speed is too fast.

· Solution: Locate the Latch Speed valve. To slow the door down, turn this valve counter-clockwise. Make a quarter-turn adjustment, test the door, and repeat until the door closes firmly and quietly into the latch.

Problem 2: The Door Closes Too Slowly or Doesn't Latch

· Cause: The main swing speed or latch speed is too slow.

· Solution:

First, adjust the Swing Speed valve. Turn it clockwise a quarter-turn to increase the speed over the main part of the swing. Test the door.

If the door moves well but still doesn't latch, adjust the Latch Speed valve. Turn it clockwise a quarter-turn to give it that final push needed to engage the strike plate.

Problem 3: The Door is Difficult to Open

· Cause: The hydraulic pressure is set too high, or the spring power is too strong. This is common on doors that are exposed to wind or that need to fire-rate.

· Solution: Look for a different type of screw, often located on the arm's pivot or at the end of the hydraulic cylinder. This is the power/spring tension adjustment. Turning this screw clockwise increases the closing force, while turning it counter-clockwise decreases it. Be very careful with this adjustment, as it requires more force and can affect the door's ability to close against air pressure or a lock.

Problem 4: The Door Opens Too Forcefully and Hits the Wall

· Cause: The backcheck feature is not engaged or is set too weakly.

· Solution: If your closer has a Backcheck valve, adjust it. Turn the backcheck screw clockwise to slow the door down just before it reaches the fully open position, preventing it from hitting the wall or stop.

Sometimes, a hydraulic door closer is beyond a simple fix. If you experience any of the following, it may be time for a replacement:

· Fluid Leak: The most obvious sign. If you see a dark, oily substance leaking from the closer, the internal seals have failed. The unit has lost its hydraulic fluid and cannot be adjusted to work properly.

· Inconsistent Operation: The door closes at different speeds randomly, even after adjustment.

· No Resistance: The door swings freely without any hydraulic resistance at all.

· Corrosion or Physical Damage: Significant rust or a bent arm can compromise the closer's function and safety.

D&D Hydraulic Door Closer :

CE Door Closer - BS EN1154 500,000 cycles test, EN1634 Fire Rated 120/180mins, EN1670 Corrosion Resistance 96 hours.

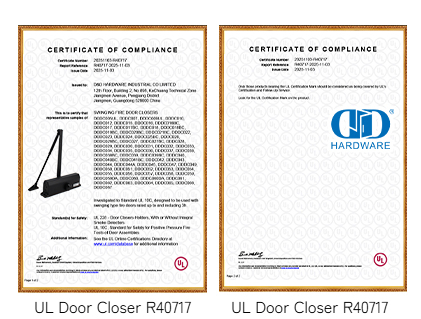

UL Door Closer - UL Listed, UL 10C Fire Rated 3 Hours, UL File No.R40717

Learning how to adjust a hydraulic door closer is a valuable and easy DIY skill that can save you time, money, and annoyance. By understanding the basic functions of the swing and latch speed valves and following the principle of small, incremental adjustments, you can restore smooth, quiet, and reliable operation to any door in your home or office.

A properly adjusted door closer not only provides convenience but also prolongs the life of your door and hardware, improves energy efficiency, and ensures the safety and security of your space. So the next time a door starts to slam, grab a screwdriver and take control.

Click here for additional details on door closers.

Now contact us.

Contact information for David Jian

Contact number: 0086-139 2903 7292

Email address: sales@danddhardware.com