Get Famous Branded Quality at Factory Cost

Pls inquire to sales@danddhardware.com

\\: +86 139 2903 7292

Author: Site Editor Publish Time: 2025-12-04 Origin: Site

There is something undeniably captivating about a bookshelf that swings open to reveal a hidden room, or a wall panel that seamlessly transforms into a doorway. While these features often feel like they belong in a mystery novel or a spy movie, they are becoming increasingly popular in modern interior design. The secret behind this magic isn't a complicated mechanism or an expensive gadget—it’s the humble, yet sophisticated, hidden door hinge.

Also known as invisible or concealed hinges, these hardware pieces are completely out of sight when the door is closed. This allows for clean, uninterrupted lines on your walls and cabinetry, making them a favorite among architects and minimalists. Whether you are building a panic room, a secret pantry, or simply want a sleek, flush door for your hallway, mastering the installation of a hidden door hinge is an essential skill for the ambitious DIYer.

Installing these hinges requires more precision than your standard butt hinge, but with the right tools and a bit of patience, you can achieve a professional result. This guide will walk you through the process, ensuring your door operates smoothly and disappears perfectly into your wall.

Before you fire up your power tools, it is helpful to understand how a hidden door hinge works. Unlike traditional hinges that have a pin visible on the outside, hidden hinges are mortised deep into the door and the frame. They use a complex link mechanism that folds inside the hinge body when the door is closed and extends outward when the door opens.

This design means there is no hardware interrupting the visual flow of the wall. However, because the mechanism is buried inside the wood, you have to remove a significant amount of material from both the door and the jamb. Precision is non-negotiable here; if the hole (mortise) is too shallow, the door won't close. If it's too deep, the door will bind or sit unevenly.

To successfully install a hidden door hinge, you will need a specific set of tools. While you can technically do this with a chisel and hammer, a router is highly recommended for the cleanest, most accurate finish.

Router: Preferably a plunge router for easy depth adjustments.

Hinge Template/Jig: Many hinge manufacturers sell specific templates for their models. This is worth the investment to ensure a perfect fit.

Drill and Bits: For pilot holes and mounting screws.

Tape Measure and Pencil: For marking precise layouts.

Chisel: To square off corners if your router bit leaves them rounded (unless you have rounded hinges).

Safety Gear: Goggles and ear protection.

The Hinges: Ensure you have the correct size for your door's weight and thickness.

Start by deciding where your hinges will sit. For a standard 80-inch door, three hinges are usually recommended to prevent warping and support the weight. A heavy solid-core door might require four.

Top Hinge: typically 5–7 inches from the top of the door.

Bottom Hinge: typically 10–11 inches from the bottom.

Middle Hinge: Centered between the top and bottom hinges.

Mark these locations clearly on both the door edge and the corresponding door jamb. Accuracy is vital here—the measurements must mirror each other exactly.

If you are using a routing template (jig), clamp it securely to the door edge at your marked location. Set the depth of your router bit to match the thickness of the hinge’s faceplate. Some hidden hinges have a two-step mortise—a shallow one for the faceplate and a deeper one for the body of the hinge. Check the manufacturer’s instructions carefully.

With the jig in place, use your router to remove the wood. Move the router in a clockwise direction to prevent the bit from grabbing the wood and causing tear-out.

First pass: Cut the shallow mortise for the plate.

Second pass: If your hinge requires a deeper pocket for the mechanism, adjust your template or router depth and make the second, deeper cut in the center.

Repeat this process for all hinge locations on the door. Then, m

Before screwing anything in, place the hinge into the mortise. It should sit flush with the surface of the wood. If it sits proud (sticks out), you need to route a little deeper. If it sinks too deep, you may need to shim it out with thin cardboard or wood veneer.

Once the fit is snug, mark the screw holes. Remove the hinge and drill pilot holes to prevent the wood from splitting. This is especially important near the edge of the door.

Secure the hinges to the door first using the provided screws. Then, lift the door into place (you will likely need a helper for this) and secure the other side of the hinges to the jamb.

One of the huge advantages of a high-quality hidden door hinge is adjustability. Most modern models are "3D adjustable," meaning you can tweak the door's position in three directions: vertical (up/down), horizontal (left/right), and depth (in/out).

Using a hex key (Allen wrench), make micro-adjustments until the gaps around the door are uniform and the face of the door is perfectly flush with the wall. This step is what separates a DIY job from a professional-looking installation.

Not all hinges are created equal. When selecting your hardware, pay close attention to the load rating. Installing a hinge rated for 40 lbs on a 100 lb solid oak door is a recipe for failure.

Additionally, look for certification marks that indicate quality and safety standards. For builders in regions requiring specific compliance, finding a CE hidden door hinge is crucial. The CE mark indicates that the hardware complies with European health, safety, and environmental protection standards. Even if you aren't in Europe, buying a CE hidden door hinge often guarantees a certain level of durability and performance testing that cheaper, unbranded alternatives lack.

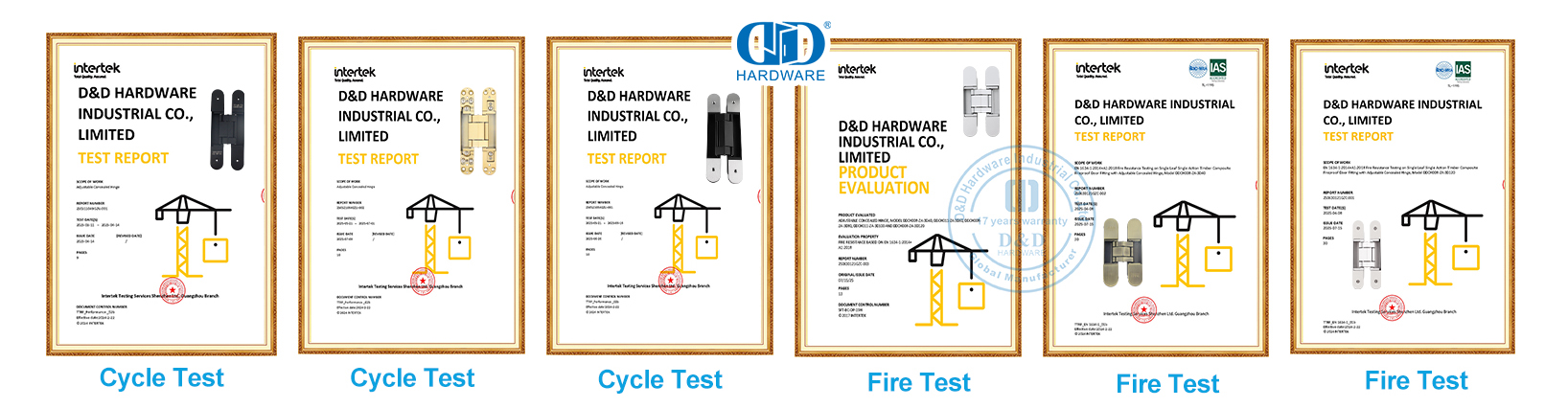

D&D concealed door hinge - BS EN1935 200,000 cycles test, EN1634 fire rated 132mins, EN1670 corrosion resistance 48 hours

The door won't close completely.

This usually happens if the mortise on the jamb side is slightly misaligned or not deep enough. Check to see if the hinge arms are binding against the wood. You may need to chisel out a small amount of extra material to give the mechanism clearance.

The door is sagging.

If the door scrapes the floor or looks crooked, check your top hinge. It carries the most load. Ensure the screws are tight and biting into solid wood (not just the veneer or drywall). If the hinge is adjustable, use the vertical adjustment screw to lift the door up.

Yes, but it can be tricky. Hollow core doors don't have solid wood all the way through. You generally need a solid block of wood where the hinge mounts. If your door doesn't have this, you may need to reinforce the mounting points with a solid wood block insert before routing.

Most high-quality hidden hinges allow for a 180-degree opening, meaning the door can swing flat against the wall. However, if you have thick casing or molding around the door, this might restrict the opening angle.

Some are, but not all. If you are installing a door between a garage and a house, or in a commercial setting, you must check the specifications to ensure the hinge maintains the fire rating of the door assembly.

Installing a hidden door hinge is a project that demands precision, but the payoff is immense. It transforms a standard entryway into an architectural feature, offering a level of sophistication that standard hinges simply can’t match. Whether you are hiding a storage closet or just cleaning up the visual lines of a modern living room, the effort you put into the installation will be rewarded every time you push that seamless panel and watch it glide open.

Click here for additional details on concealed door hinges.

Now contact us.

Contact information for David Jian

Contact number: 0086-139 2903 7292

Email address: sales@danddhardware.com