Get Famous Branded Quality at Factory Cost

Pls inquire to sales@danddhardware.com

\\: +86 139 2903 7292

A door closer that won't stay shut can be frustrating and compromise your home's security and energy efficiency. Whether you're dealing with a broken spring mechanism or simply want to upgrade to a more reliable model, installing a new door closer is a straightforward DIY project that most homeowners can tackle in under an hour.

This guide will walk you through everything you need to know about installing a door closer, from selecting the right hardware to making final adjustments. With the right tools and a bit of patience, you'll have a smoothly functioning door that closes automatically every time.

Before diving into the installation process, gather these essential tools and materials:

Tools:

· Power drill with bits

· Screwdriver set

· Level

· Measuring tape

· Pencil for marking

· Safety glasses

Materials:

· Door closer unit

· Mounting screws (usually included)

· Wall anchors (if mounting to drywall)

· Lubricant spray

Most door closer kits come with detailed instructions and all necessary hardware. However, double-check that you have the right type of closer for your door weight and opening direction.

Not all door closers are created equal. The type you need depends on several factors:

Door Weight and Size: Standard residential door closers handle doors up to 150 pounds. Heavier doors require commercial-grade closers with higher spring tension.

Mounting Location: Door closers can be mounted on the door frame (top jamb), on the door itself, or on the wall beside the door. Top jamb mounting is most common for residential applications.

Opening Direction: Ensure your door closer is compatible with whether your door opens inward or outward, and from left to right or right to left.

Adjustability Features: Look for models with adjustable closing speed and latching speed controls for optimal performance.

If you're replacing an existing door closer, start by removing the old unit:

Disconnect the closer arm from the door bracket by removing the connecting pin or screw. Support the closer body while removing the mounting screws from the frame. Clean the mounting area thoroughly, removing any old screws or debris that might interfere with the new installation.

Take note of the old mounting holes—you may be able to reuse them if the new closer has a similar mounting pattern.

Proper positioning is crucial for smooth door operation. Most door closers mount to the top of the door frame, centered above the door.

Hold the closer body against the frame where you plan to mount it. Use a level to ensure it's perfectly horizontal—even slight tilting can cause operational problems. Mark the screw holes with a pencil, then double-check your measurements before drilling.

For the door bracket, position it on the door about 6-8 inches from the hinge side. The exact distance will depend on your specific closer model and door width.

Drill pilot holes at your marked locations to prevent wood splitting. If you're mounting to a metal frame, use appropriate metal drill bits. For hollow doors or drywall mounting, install proper anchors before inserting screws.

Attach the closer body to the frame using the provided screws. Tighten securely, but don't overtighten as this can strip the holes or damage the closer housing. The unit should sit flush against the mounting surface.

Mount the door bracket to the door using the same careful marking and drilling process. The bracket must align properly with the closer body for smooth operation.

Connect the closer arm between the main unit and door bracket. Most modern closers use a simple pin or screw connection system. Ensure the arm moves freely through its full range of motion without binding or interference.

Test the door's swing to verify proper alignment. The door should open and close smoothly without the arm hitting the frame or other obstacles.

Most door closers have adjustment screws that control closing speed and latching speed. These are typically located on the closer body and marked clearly.

Closing Speed: This controls how fast the door closes from fully open to about 15 degrees from closed. Turn clockwise to slow down, counterclockwise to speed up.

Latching Speed: This controls the final closing motion from about 15 degrees open to fully closed. Proper adjustment ensures the door closes completely without slamming.

Make small adjustments—usually no more than a quarter turn at a time—and test the door between adjustments. The goal is smooth, controlled closing that ensures the door latches securely every time.

Even with careful installation, you might encounter some issues:

Door Won't Stay Closed: Check that the latching speed isn't too fast, causing the door to bounce back. Also verify that the door and frame are properly aligned.

Door Closes Too Slowly: Adjust the closing speed screw counterclockwise, but make small increments to avoid overcorrection.

Arm Hits Frame or Door: Recheck your mounting positions. The arm should clear all obstacles throughout its range of motion.

Uneven Closing Motion: This often indicates the closer body isn't level. Remove and reinstall, paying careful attention to proper alignment.

A properly installed door closer can provide years of reliable service with minimal maintenance:

Apply a few drops of lubricant to pivot points annually. Periodically check mounting screws for tightness, especially during the first few months after installation. Keep adjustment screws clean and protected from weather if the closer is exposed to outdoor conditions.

Avoid forcing the door beyond its normal range—this can damage internal components and void your warranty.

Installing a door closer transforms a problematic door into a reliable, self-closing barrier that enhances security and energy efficiency. With proper installation and occasional maintenance, your new door closer will provide smooth, consistent operation for many years.

Take your time during installation, make careful measurements, and don't hesitate to make small adjustments until the door closes exactly how you want it. The hour you spend on proper installation will save you from headaches down the road.

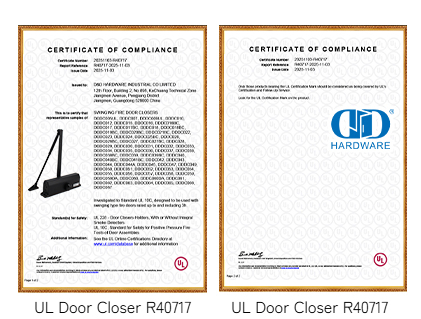

D&D Fire Rated Door Closer :

CE Door Closer - BS EN1154 500,000 cycles test, EN1634 Fire Rated 120/180mins, EN1670 Corrosion Resistance 96 hours.

UL Door Closer - UL Listed, UL 10C Fire Rated 3 Hours, UL File No.R40717

Click here for additional details on door closers.

Now contact us.

Contact information for David Jian

Contact number: 0086-139 2903 7292

Email address: sales@danddhardware.com