Get Famous Branded Quality at Factory Cost

Pls inquire to sales@danddhardware.com

\\: +86 139 2903 7292

Author: Site Editor Publish Time: 2025-12-27 Origin: Site

Few DIY projects hit a snag faster than replacing a door hinge. You unscrew the old, squeaky hardware, head to the hardware store, grab a pack that looks "about right," and return home only to find the screw holes don't align, the corners don't fit the mortise, or the door simply won't close.

It is a common assumption that hardware is standardized. While there are industry standards that manufacturers follow, the short answer to the question is no, exterior door hinges are not universal.

If you are replacing a hinge on a residential front door or specifying a commercial building door hinge for a high-traffic entrance, understanding the specific variables is crucial. A hinge that fits physically might not be rated for the weight of the door, and a hinge that looks robust might corrode within months if chosen for the wrong environment.

This guide will break down exactly why hinges aren't universal, how to measure what you have, and how to select the perfect replacement to ensure security and longevity.

When we talk about whether hinges are universal, we are usually talking about three things: size, shape, and screw pattern. While you might get lucky and find a direct match off the shelf, varying manufacturing standards over the last century mean there are thousands of combinations.

Exterior doors pose a specific challenge compared to interior doors. They are heavier, thicker, and exposed to the elements. Consequently, the hardware used to hang them is more robust and varies significantly depending on the age of the building and the intended use (residential vs. commercial).

Here are the primary factors that prevent hinges from being interchangeable:

Hinge Dimensions (Height and Width)

Corner Radius (Shape)

Leaf Thickness and Weight Rating

Screw Hole Patterns

Security Features

Let's dive deeper into these categories to help you identify exactly what you need.

The most obvious difference between hinges is the physical size. Exterior doors are generally larger and heavier than interior doors, requiring larger hinges to support the load without sagging.

For most standard residential entry doors (1-3/4" thick), the most common hinge size is 4 inches. However, older homes or lighter exterior doors might use 3.5-inch hinges, though this is less common for entryways.

When dealing with a commercial building door hinge, the standard jumps up. Commercial doors often see high abuse and heavy traffic. Consequently, you will typically see 4.5-inch or 5-inch hinges. These are designed to displace the weight of heavy steel or solid wood doors over a larger surface area.

Installing a 3.5-inch residential hinge on a heavy commercial security door is a recipe for failure; the hinge will eventually bend, or the screws will rip out of the frame.

If you look at the cutout (mortise) on the edge of your door where the hinge sits, you will notice the corners are either sharp right angles or rounded curves. This is one of the most common reasons "universal" replacements fail fitting tests.

There are three main styles:

Square Corner: The corners are sharp 90-degree angles. This is standard for a commercial building door hinge and older residential homes where mortises were cut by hand with a chisel.

1/4" Radius: A slight curve at the corner. This is common in modern residential construction.

5/8" Radius: A much more pronounced curve. This is also common in residential settings.

1

Pro Tip: The Coin Test

If you aren't sure which radius you have, grab some change from your pocket.

If a dime fits perfectly in the corner, you have a 1/4" radius.

If a quarter fits perfectly in the corner, you have a 5/8" radius.

1

Exterior hinges must withstand two forces that interior hinges do not: weather and extreme weight.

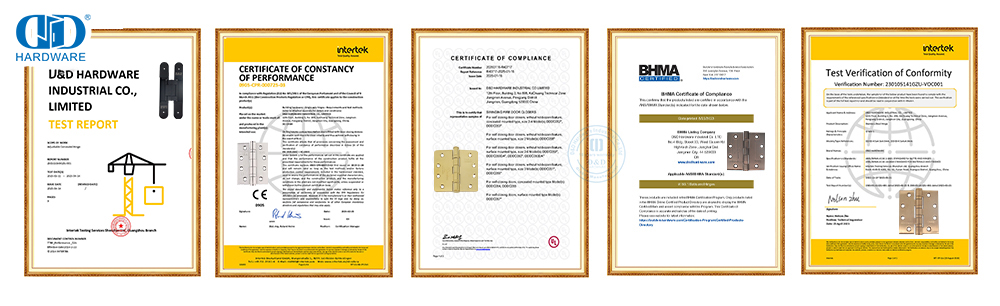

️✔ CE Door Hinge - BS EN1935 200,000 cycles test, EN1634 Fire Rated 192mins/260mins, EN1670 Corrosion Resistance 240 hours.

️✔ UL Door Hinge - UL/cUL Listed, UL 10C Fire Rated 3 Hours, File No.R38013

✔ BHMA Door Hinge - ANSI/BHMA 156.1 and ANSI/BHMA 156.18

✔ ANSI Door Hinge - ANSI Grade 1 2,500,000 cycles test, ANSI Grade 2 1,500,000 cycles test

✔ CE Concealed Hinge-BS EN1935 200,000 cycles test, EN1634 Fire Rated 132mins, EN1670 Corrosion Resistance 48 hours.

Steel is the most common material for hinges, but it rusts. For exterior applications, standard steel hinges are often plated (e.g., brass plated or satin nickel). However, if the plating scratches, rust will set in.

For coastal areas or commercial buildings, Stainless Steel (Grade 304 or 316) or Solid Brass is recommended. D&D Hardware, for example, specializes in manufacturing stainless steel hinges that meet rigorous international standards (CE, UL, ANSI) to prevent corrosion while maintaining structural integrity.

This is the thickness of the metal plate itself. If you buy a cheap replacement hinge, the metal might be thinner than your original. When you install it, the door might sit too deep in the frame, causing it to bind against the trim when you try to close it. Conversely, if the hinge is too thick, the door won't close all the way.

Application | Typical Hinge Height | Typical Leaf Thickness |

|---|---|---|

Interior Residential | 3.5" | 0.085" - 0.097" |

Exterior Residential | 4.0" | 0.085" - 0.109" |

Standard Commercial | 4.5" | 0.134" (Standard Weight) |

Heavy Duty Commercial | 4.5" - 5.0" | 0.180" - 0.190" (Heavy Weight) |

The distinction between residential and commercial hardware is significant. A commercial building door hinge is engineered for "high frequency" use. While a home front door might be opened 10 times a day, a storefront door might be opened 500 times a day.

To handle this, commercial hinges often utilize ball bearings.

Plain Bearing: Standard for residential. The metal barrels rub directly against each other (or a plastic washer). They wear out over time, producing "black dust" (graphite) and squeaking.

Ball Bearing: Essential for exterior and commercial doors. The hinge pivots on hardened steel bearings lubricated with grease. They provide a smoother operation and prevent the door from sagging over years of heavy use.

If your exterior door is solid wood or metal, always upgrade to ball-bearing hinges, even if the previous ones were plain bearing.

This is the variable that frustrates homeowners the most. You found a 4-inch hinge with a 5/8" radius corner—a perfect match, seemingly. But when you go to install it, the screw holes in the new hinge stick halfway over the old holes in the door.

Manufacturers use different hole patterns (often called "arch" or "zigzag" patterns). There is no universal standard for where the screws go.

The Solution:

If you cannot find a hinge with an exact screw hole match, you will need to fill the old holes. Glue a wooden golf tee or a dowel into the old screw hole, snap it off flush, sand it smooth, and then drill new pilot holes for your new hinge. Do not try to angle a screw into a half-filled hole; it will pull the hinge out of alignment.

Exterior doors often swing outward, especially in commercial buildings or hurricane-prone areas. This means the barrel of the hinge is exposed to the outside.

If a hinge is "universal" and cheap, a burglar can simply pop the pin out of the hinge with a screwdriver and remove the door, bypassing the lock entirely.

For exterior applications, you must look for NRP (Non-Removable Pin) hinges. These hinges have a set screw inserted into the barrel that is only accessible when the door is open. If the door is closed, the pin cannot be removed. Alternatively, security studs (a metal tab on one leaf that fits into a hole on the other) prevent the door from being slid out of the frame even if the pin is cut.

To summarize why you can't just grab any hinge off the shelf, review the differences below:

Feature | Residential Hinge | Commercial Hinge |

|---|---|---|

Common Size | 3.5" or 4.0" | 4.5" or 5.0" |

Corner Shape | Often Radius (Round) | Often Square |

Bearing Type | Plain or Ball Bearing | Ball Bearing (Standard) |

Base Material | Steel or Brass | Stainless Steel, Steel, Bronze |

Fasteners | Wood Screws | Machine Screws (for metal doors) |

Thickness | Thin (.085" - .097") | Thick (.134" - .190") |

Fire Rating | Rarely Rated | Often Certified (UL/ANSI) |

If you are planning to swap out your hinges, follow these steps to ensure a proper fit.

Measure Height and Width: Open the door and measure the height of the hinge plate.

Check the Corners: Use the coin test (Dime vs. Quarter) or check for square corners.

Count the Knuckles: Standard hinges usually have 5 knuckles (the interlocking sections). Some specialized hinges have 3.

Check the Screw Pattern: It is rare to find a perfect match, so be prepared to plug and re-drill holes.

Upgrade the Screw Length: When installing exterior hinges, replace at least one screw per hinge with a long (3-inch) screw that goes all the way into the wall stud. This significantly prevents door sagging and improves security against kick-ins.

1

If you are dealing with a commercial project, fire-rated doors, or unique architectural requirements, big-box store "universal" hinges will not suffice. You need hardware that meets specific safety codes (like EN 1935 or ANSI/BHMA standards).

Manufacturers like D&D Hardware specialize in this level of precision. With over 17 years of experience, they provide hinges that are rigorously tested for fire safety (UL 10C) and durability. Whether you need heavy-duty stainless steel hinges for a hospital or corrosion-resistant hardware for a seaside hotel, relying on a certified manufacturer ensures your doors operate safely and smoothly for decades.

Q: Can I replace just one hinge on my door?

A: It is not recommended. If you mix old worn hinges with a stiff new hinge, the axis of rotation may differ slightly, causing the door to bind or the new hinge to bear too much weight. It is best to replace all hinges on a door at the same time.

Q: What is a "swaged" hinge?

A: Most standard door hinges are swaged, meaning the metal leaves are slightly offset so that when the hinge closes, the leaves sit flat against each other with a small gap. This allows the door to close without binding. "Flatback" hinges are not swaged and are typically used for surface-mounted applications, not standard doors.

Q: How do I know if I need a commercial grade hinge?

A: If the door is in a place of business, is exceptionally heavy (over 150 lbs), or is used more than 20 times a day, you should opt for a commercial-grade, ball-bearing hinge.

Q: Are black hinges okay for exterior use?

A: Yes, matte black is a popular finish. However, ensure the base material is stainless steel or galvanized steel if it is an exterior door. If it is just black paint over regular steel, it will rust quickly outdoors.

So, are exterior door hinges universal? Absolutely not.

From the radius of the corners to the thickness of the steel, the variations are too vast to assume compatibility. While this might seem like a headache, these variations exist to ensure that every specific door—whether it's the front entry of a cottage or the fire exit of a warehouse—has the exact hardware it needs to function safely.

By taking the time to measure your existing hardware and understanding the difference between residential and commercial building door hinge requirements, you can save yourself the hassle of returns and the frustration of a door that just won't close.

For projects requiring guaranteed durability and certified safety, always look beyond the "universal" bin and source from dedicated hardware specialists who understand the engineering behind the metal.

Click here for additional details on door hinges.

Now contact us.

Contact information for David Jian

Contact number: 0086-139 2903 7292

Email address: sales@danddhardware.com