Get Famous Branded Quality at Factory Cost

Pls inquire to sales@danddhardware.com

\\: +86 139 2903 7292

Author: Site Editor Publish Time: 2025-12-25 Origin: Site

If you have ever tried to replace an existing door only to find the new hinges don't line up with the old frame, you know the frustration firsthand. It seems like a simple swap—take the old door off, put the new one on—but the reality of door hardware is rarely that straightforward.

One of the most common questions homeowners, contractors, and building managers ask is: Are exterior door hinge locations standard? The short answer is no, not entirely. While there are industry norms and common practices, "standard" is a loose term in the world of door manufacturing. Different manufacturers, regional preferences, and door types (residential vs. commercial) all play a role in where those hinges sit.

In this guide, we will explore why hinge locations vary, the differences between residential and commercial standards, and how to measure correctly to ensure a perfect fit for your next project.

It is easy to assume that all doors are created equal, but the positioning of exterior door hinges can vary significantly depending on who made the door and when it was manufactured.

There isn't a single, governing law that forces every manufacturer to place hinges at the exact same coordinates. Instead, manufacturers have their own "standard" patterns. For example, one brand might place the top hinge 5 inches from the top of the door, while another places it 7 inches down.

Several factors influence these variations:

Manufacturer Preferences: Each brand has its own templates and machinery setups.

Door Height: A standard 6'8" door has a different hinge pattern than an 8'0" tall door.

Regional Differences: East Coast and West Coast manufacturers in the United States sometimes use slightly different standard spacings.

Material: Wood, steel, and fiberglass doors often have different reinforcement points for hinges.

Because of this lack of universality, purchasing a "slab" door (just the door itself, without the frame) to fit an existing jamb often requires custom machining or careful measurement to match the existing hinge locations.

The biggest divide in hinge placement standards occurs between residential and commercial applications. These two categories operate under different codes and usage requirements, leading to distinct hardware configurations.

In residential construction, the most common standard for a 6'8" door involves three hinges. While measurements can vary, a typical layout often looks like this:

Top Hinge: 5 to 7 inches from the top of the door.

Bottom Hinge: 9 to 11 inches from the bottom of the door.

Middle Hinge: Centered between the top and bottom hinges.

However, "typical" does not mean guaranteed. If you are replacing a front entry door on a home built in the 1980s, the hinge pattern might differ from what you find in a hardware store today.

For a door hinge for commercial building applications, consistency is more critical due to strict fire codes and heavy usage. Commercial doors are often steel (hollow metal) or solid wood and are much heavier than residential doors.

Commercial standards often follow specific templates set by organizations like the Steel Door Institute (SDI) or guidelines for fire-rated doors.

Common Commercial Hinge Layout (7'0" Door):

Top Hinge: 5 inches from the top of the door header to the top of the hinge.

Bottom Hinge: 10 inches from the bottom finished floor to the bottom of the hinge.

Intermediate Hinges: Spaced equally between the top and bottom hinges.

When sourcing hardware for these projects, working with a specialized supplier like D&D HARDWARE INDUSTRIAL Co.Ltd. ensures that you get hinges rated for the correct weight, frequency of use, and fire safety compliance.

Location isn't the only variable; the physical size and shape of the exterior door hinges themselves can vary.

Residential: Typically 3.5 inches or 4 inches in height.

Commercial: Typically 4.5 inches or 5 inches in height to support heavier loads.

1

The corners of the hinge leaves also come in different styles. If you buy a hinge with square corners but your door is routed for rounded corners, it won't fit.

Corner Style | Description | Common Application |

|---|---|---|

Square Corner | 90-degree sharp corners. | Commercial doors; older residential doors. |

1/4" Radius | Rounded corners with a 1/4-inch radius curve. | Common in modern residential doors. |

5/8" Radius | Rounded corners with a slightly wider, 5/8-inch radius curve. | Common in residential doors. |

Since you cannot rely on a universal standard, the only way to ensure a replacement door fits is to measure the existing hinge locations accurately. This is crucial if you are ordering a custom door or machining a new slab to fit an old jamb.

Step-by-Step Measurement Guide:

Use a Tape Measure: Hook your tape measure to the top edge of the door (not the frame).

Measure to the Top of Each Hinge:

Measure from the top of the door to the top edge of the first (highest) hinge.

Measure from the top of the door to the top edge of the middle hinge.

Measure from the top of the door to the top edge of the bottom hinge.

Check Hinge Size: Measure the height and width of the hinge plate itself.

Check Corner Radius: Determine if the corners are square, 1/4" radius, or 5/8" radius.

If you are communicating these measurements to a manufacturer, always clarify if you are measuring to the top of the hinge or the center of the hinge, as this can cause confusion.

Selecting the correct hinge goes beyond just getting the screw holes to line up. Exterior doors are exposed to the elements and security risks, meaning the quality of the hardware matters immensely.

Material Matters:

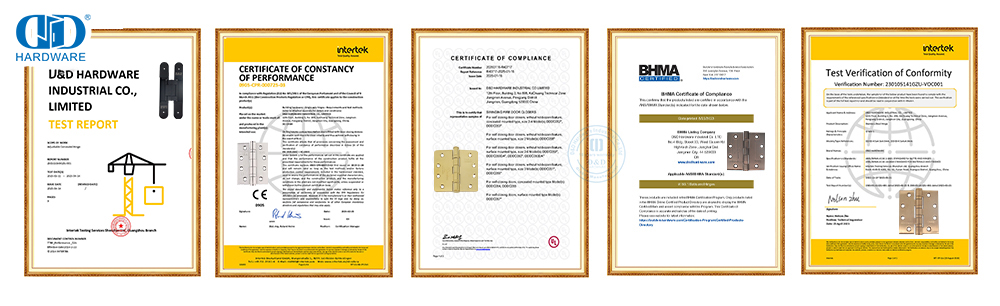

Stainless Steel: The gold standard for exterior doors. It resists rust and corrosion, making it essential for coastal areas or humid climates. D&D HARDWARE INDUSTRIAL Co.Ltd. specializes in stainless steel hinges that meet international standards like CE, UL, ANSI, and BHMA.

Brass: Offers a classic look and resists corrosion but is softer than steel.

Steel (Plated): Strong but prone to rust if the plating (like satin nickel or oil-rubbed bronze) is scratched or worn down.

Security Features:

For exterior doors that swing outward, hinge security is vital. Because the hinge pin is exposed on the outside, intruders could theoretically pop the pin out and remove the door.

NRP (Non-Removable Pin) Hinges: These have a set screw in the barrel that is only accessible when the door is open, preventing pin removal.

Security Studs: A stud on one leaf locks into a hole on the other leaf when the door is closed, preventing the door from being removed even if the pin is cut.

1

To give you a general idea of what to expect, here is a reference table for common hinge locations. Note: These are examples and should not be used in place of actual measurement.

Door Type | Door Height | Top Hinge Location | Bottom Hinge Location | Intermediate Hinge(s) |

|---|---|---|---|---|

Standard Residential | 6'8" | 7" from top | 11" from bottom | Centered |

Standard Commercial | 7'0" | 5" from top | 10" from bottom | Equally spaced |

8-Foot Door | 8'0" | 5" from top | 10" from bottom | Two intermediate hinges, equally spaced |

️✔ CE Door Hinge - BS EN1935 200,000 cycles test, EN1634 Fire Rated 192mins/260mins, EN1670 Corrosion Resistance 240 hours.

️✔ UL Door Hinge - UL/cUL Listed, UL 10C Fire Rated 3 Hours, File No.R38013

✔ BHMA Door Hinge - ANSI/BHMA 156.1 and ANSI/BHMA 156.18

✔ ANSI Door Hinge - ANSI Grade 1 2,500,000 cycles test, ANSI Grade 2 1,500,000 cycles test

✔ CE Concealed Hinge-BS EN1935 200,000 cycles test, EN1634 Fire Rated 132mins, EN1670 Corrosion Resistance 48 hours.

While the construction industry strives for consistency, exterior door hinges do not follow a single, unbreakable universal standard. Variations in manufacturer templates, regional practices, and building codes mean that assumptions can lead to costly mistakes.

Whether you are retrofitting a historic home or specifying hardware for a new office complex, accurate measurement is your best tool. Always verify the hinge pattern on the existing frame before ordering a new door slab.

For projects demanding high durability and compliance with strict safety codes, partnering with a trusted manufacturer is essential. D&D HARDWARE INDUSTRIAL Co.Ltd. offers a comprehensive range of certified hardware—including ANSI, UL, and CE-rated hinges—designed to meet the rigorous demands of both commercial and residential projects. By choosing the right hardware and measuring twice, you ensure your exterior doors remain secure, functional, and perfectly aligned for years to come.

Click here for additional details on door hinges.

Now contact us.

Contact information for David Jian

Contact number: 0086-139 2903 7292

Email address: sales@danddhardware.com