Get Famous Branded Quality at Factory Cost

Pls inquire to sales@danddhardware.com

\\: +86 139 2903 7292

Author: Site Editor Publish Time: 2025-12-24 Origin: Site

Your front door does more than just welcome guests. It protects your family, keeps out the weather, and secures your belongings. While many homeowners obsess over high-tech locks and solid wood slabs, they often overlook the small metal components holding it all together: the screws.

The screws in your exterior door hinge are the unsung heroes of home security. If they are too short, a swift kick could easily break the door frame. If they are the wrong gauge, the hinge won't sit flush, leading to a door that scrapes the floor or refuses to close.

Choosing the right screw size isn't just about carpentry; it's about safety and functionality. When you invest in high-quality hardware from manufacturers like D&D HARDWARE INDUSTRIAL Co.Ltd., you want to ensure the installation is just as robust as the product itself.

In this guide, we will break down exactly what size screw you need for an exterior door hinge, why the length matters for security, and how to choose the right material to prevent rust.

Before we talk about numbers, it is important to understand the mechanics of a door frame. Most pre-hung doors come with short screws, usually only 3/4 of an inch long. These screws only penetrate the door jamb (the trim), not the solid stud structure behind the wall.

For an interior closet door, this is fine. For a heavy exterior door, it is a problem. The weight of the door pulls on these short screws over time, causing the door to sag. More importantly, these short screws offer very little resistance against forced entry.

To secure an exterior door hinge properly, you need screws that go through the hinge, through the jamb, and deep into the solid wood stud.

The short answer: You should use screws that are at least 3 inches (76mm) long.

The detailed answer:

Standard residential hinges usually have three or four holes. You do not necessarily need to replace every single screw with a 3-inch anchor, but you must replace at least one or two per hinge.

By driving a 3-inch screw into the center hole of each hinge, you anchor the door to the structural framework of the house. This prevents the door from sagging over time and drastically increases the force required to kick the door in.

Here is a quick reference guide for screw lengths based on application:

Application | Recommended Screw Length | Purpose |

|---|---|---|

Standard Fix | 3/4 inch to 1 inch | Keeps the hinge attached to the jamb (light duty). |

Sagging Door | 2.5 inches to 3 inches | Pulls the jamb tighter to the stud to lift the door. |

Security Reinforcement | 3 inches | Anchors the door to the structural stud for maximum strength. |

Heavy Commercial Doors | 3 inches + | Required for heavy steel or solid wood doors (check D&D Hardware specs). |

Length is only half the equation. You also need the right diameter, known as the gauge. If the screw is too thin, it won't grip the wood. If it is too thick, the screw head will stick out, and the door won't close properly.

Most standard residential exterior door hinges use a #9 or #10 screw.

#9 Screws: These are the most common for residential hinges. The head sits flush in the countersunk hole of most standard hinges.

#10 Screws: Slightly thicker and stronger. These are common in heavy-duty residential or light commercial hinges.

#12 Screws: These are typically found on larger commercial doors using heavy-duty ball-bearing hinges.

If you are replacing screws on an existing hinge, remove one old screw and match it. If you are installing new hardware from D&D HARDWARE INDUSTRIAL Co.Ltd., check the product specifications included with your ANSI or UL-rated hinges.

Using the wrong head type is a common DIY mistake. Hinge holes are "countersunk," meaning they are shaped like a cone so the screw sits flat with the surface of the metal.

Flat Head: This is the correct type. The top is flat, and the underside is tapered. It sits flush with the hinge plate.

Pan Head or Round Head: Do not use these. The heads are rounded and sit on top of the hinge. If you use these, your door will likely bind against the frame and fail to close.

For the drive type (the slot for your screwdriver), Phillips is the industry standard for door hinges. However, square drive (Robertson) or Star drive (Torx) are gaining popularity because they are less likely to strip out when you apply the high torque needed to drive a 3-inch screw into a stud.

Exterior doors face rain, snow, humidity, and temperature changes. If you use a standard steel screw, it will eventually rust. Rusty screws lose strength and can stain your beautiful door finish with orange streaks.

You must match the screw material to your hinge material to prevent corrosion and keep the aesthetic consistent.

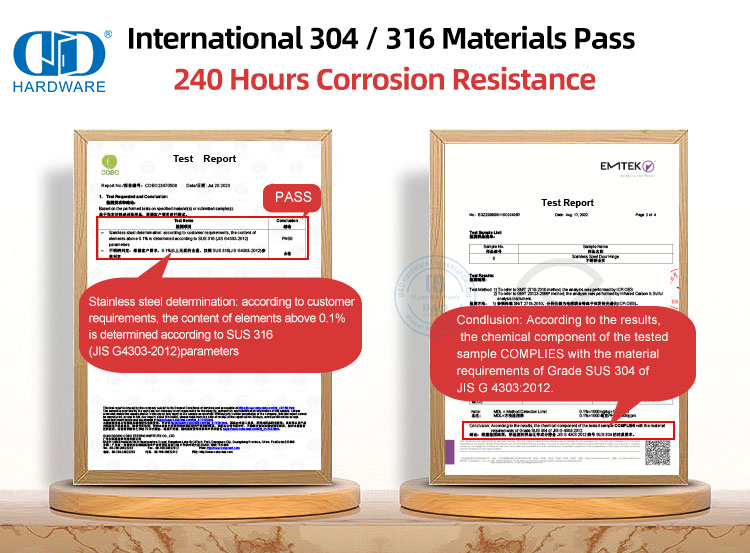

This is the gold standard for exterior usage. If you have purchased a stainless steel exterior door hinge from D&D Hardware, you should use stainless steel screws. Grade 304 is excellent for general outdoor use, while Grade 316 is recommended for coastal areas with salt air.

Solid brass screws are resistant to corrosion and look beautiful. However, brass is a soft metal. If you try to drive a 3-inch brass screw into a stud, the head might snap off.

Pro Tip: Drive a steel screw in first to create the threads, remove it, and then install the brass screw.

These offer some rust protection and are cheaper than stainless steel. They are acceptable for painted hinges but may eventually corrode if the coating is scratched during installation.

No, you should avoid this. When two different metals touch in the presence of moisture (like on an exterior door), a process called galvanic corrosion occurs. This causes the metals to break down faster. Always try to match the screw material to the hinge material.

If your screw keeps spinning and won't tighten, the wood fibers are stripped. You don't necessarily need a bigger screw.

Remove the screw.

Dip a few wooden toothpicks or a golf tee in wood glue.

Jam them into the hole and break them off flush.

Wait for the glue to dry.

Drive your screw back in. The new wood provides a fresh grip.

Yes. Commercial doors often use machine screws rather than wood screws because they are often installed into metal frames (hollow metal jambs). These require specific threading (like 12-24 machine threads). D&D Hardware specializes in these types of architectural hardware solutions. Always check the door frame type before buying screws.

Upgrading your hinge screws is one of the cheapest and most effective security upgrades you can make. Here is how to do it safely:

Support the door: Place a wedge or shim under the door so it doesn't drop when you remove screws.

Do one at a time: Never remove all the screws from a hinge at once. The heavy door will fall.

Start with the top hinge: Remove the center screw from the jamb side (the side attached to the wall).

Drill a pilot hole: Since you are using a long 3-inch screw, drill a thin pilot hole into the stud to prevent the wood from splitting.

Drive the new screw: Insert your 3-inch screw and tighten it until it is flush.

Repeat: Do this for the center screw on the middle and bottom hinges.

The strength of your exterior door depends heavily on the hardware you choose and how you install it. A high-quality hinge from a trusted manufacturer like D&D Hardware provides the smooth operation and durability required for safety standards like UL and ANSI. However, that hinge needs the right anchor.

By swapping out standard factory screws for 3-inch, flat-head screws made of weather-resistant material, you ensure your door remains secure, functional, and visually appealing for years to come.

If you are looking for certified door hardware solutions, including heavy-duty hinges suitable for rigorous use, explore the full catalog at D&D HARDWARE INDUSTRIAL Co.Ltd..

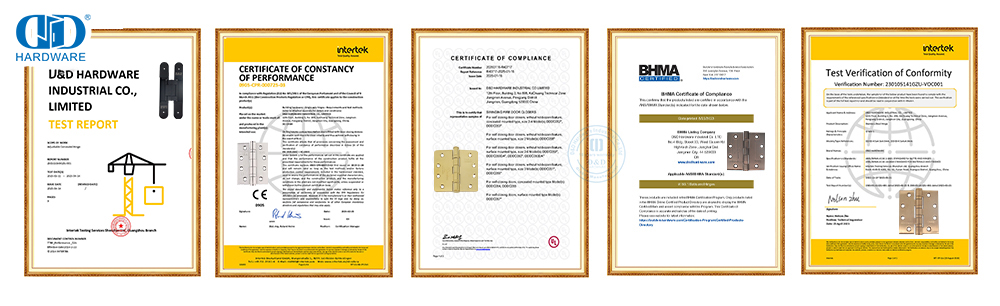

D&D Door Hinge Certification:

️✔ CE Door Hinge - BS EN1935 200,000 cycles test, EN1634 Fire Rated 192mins/260mins, EN1670 Corrosion Resistance 240 hours.

️✔ UL Door Hinge - UL/cUL Listed, UL 10C Fire Rated 3 Hours, File No.R38013

✔ BHMA Door Hinge - ANSI/BHMA 156.1 and ANSI/BHMA 156.18

✔ ANSI Door Hinge - ANSI Grade 1 2,500,000 cycles test, ANSI Grade 2 1,500,000 cycles test

✔ CE Concealed Hinge-BS EN1935 200,000 cycles test, EN1634 Fire Rated 132mins, EN1670 Corrosion Resistance 48 hours.

Click here for additional details on door hinges.

Now contact us.

Contact information for David Jian

Contact number: 0086-139 2903 7292

Email address: sales@danddhardware.com