Get Famous Branded Quality at Factory Cost

Pls inquire to sales@danddhardware.com

\\: +86 139 2903 7292

Author: Site Editor Publish Time: 2025-11-15 Origin: Site

Choosing the appropriate hydraulic door closer is a critical decision that impacts not only the functionality and longevity of a door but also the safety, accessibility, and energy efficiency of a building. A poorly selected closer can lead to doors that slam, fail to latch, become difficult to open, or compromise fire safety. This guide provides a detailed, factor-based approach to ensure you select a closer that is perfectly matched to your specific application, ensuring optimal performance and compliance.

The most fundamental step is aligning the closer's power size with the physical characteristics of the door. Hydraulic door closers are classified by power size, typically following the EN 1154 standard with grades from 1 to 7 (where EN1 is the lightest and EN7 the most powerful).

-Lightweight Interior Doors (EN2-3): Suitable for small, lightweight doors, such as those for closets or lightweight office partitions. These doors typically weigh less than 30kg (66 lbs) and are up to 75cm (30 inches) wide.

-Standard Interior Doors (EN3-4): This is the most common range for standard interior commercial and residential doors. These doors generally weigh between 40-80kg (88-176 lbs) and are up to 110cm (44 inches) wide.

-Heavy/Exterior Doors (EN4-6): Required for larger, heavier doors, including main entrances, exterior doors, and doors in windy locations. This grade can handle doors weighing 80-120kg (176-265 lbs) and widths up to 160cm (63 inches).

-Extra-Heavy/Industrial Doors (EN6-7): Reserved for the most demanding applications, such as industrial doors, massive timber doors, or doors with exceptionally high wind loads.

Critical Consideration: Selecting an undersized closer will result in a door that fails to close or latch securely. Conversely, an oversized closer will make the door difficult to open, posing an accessibility issue and potentially violating building codes like the Americans with Disabilities Act (ADA).

For any fire-rated door assembly, the door closer is not an accessory but a vital life-safety component. Its role is to ensure the door closes completely and latches in the event of a fire, maintaining the integrity of the fire barrier to prevent the spread of flames and smoke.

-In Europe (CE Marking): The closer must be certified to EN 1154 for mechanical performance and, crucially, must have passed fire resistance testing according to EN 1634. The manufacturer must provide a Declaration of Performance (DoP).

D&D CE Door Closer - BS EN1154 500,000 cycles test, EN1634 fire rated 120/180mins, EN1670 corrosion resistance 240 hours

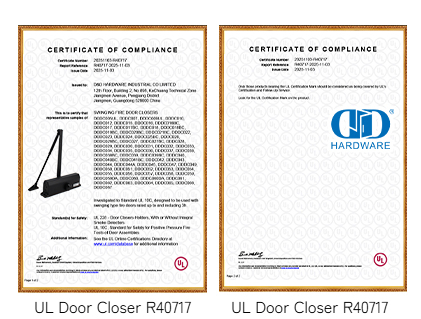

-In North America (UL Listing): The closer must be UL Listed and have passed UL 10C for positive pressure fire tests. The specific UL listing mark and file number (e.g., R40717) should be verifiable.

D&D UL Door Closer - UL Listed, UL 10C Fire Rated 3 hours, UL File NO.R40717

Using a non-fire-rated closer on a fire door invalidates the door's certification and creates a significant safety hazard.

Durability is directly linked to the volume of traffic a door experiences. A closer in a low-traffic office will have a very different lifespan than one on a school or hospital door.

-Low Traffic (Residential, Private Offices): Standard-grade closers are typically sufficient, often rated for 200,000 cycles.

-Medium Traffic (General Office Buildings, Retail): Heavy-duty commercial-grade closers (EN 1154 Grade 4) are recommended, with cycle test ratings of 300,000 to 500,000.

-High Traffic (Hospitals, Schools, Airports, Malls): Maximum-duty closers (EN 1154 Grade 5-6) are essential. These are built to withstand 500,000 to over 1,000,000 cycles, ensuring long-term reliability and reduced maintenance in critical, high-use environments.

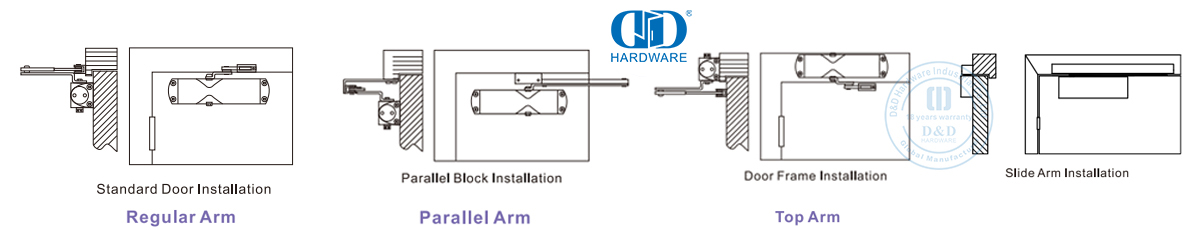

The door's design, material, and aesthetic requirements dictate the best type of closer installation.

-Overhead Surface-Mounted: The most common and easiest to install and maintain. Ideal for standard wood and metal doors where aesthetics are not the primary concern.

-Concealed in the Door Frame (Jamb-Mounted): Provides a clean, minimalist look as the closer body is hidden within the door frame. Requires precise machining during installation.

-Concealed in the Door Head (Transom-Mounted): Similar to jamb-mounted but hidden in the header above the door, offering a seamless appearance.

-Floor Springs: The entire mechanism is installed in the floor, making it completely invisible from above. This is the premier solution for heavy glass doors and monumental doors in high-end architectural projects.

The operating environment significantly affects closer performance.

-Temperature Extremes: Standard hydraulic fluid can become sluggish in cold weather and thin in hot weather. For exterior doors or unheated spaces, specify closers with a temperature-stable fluid designed to perform consistently across a wide range (e.g., -20°C to +80°C).

-Corrosive Environments: In coastal areas, swimming pools, or industrial settings, choose closers with a high corrosion resistance rating per EN 1670 Class 4 or 5, which signifies successful passage of 240 to 480 hours of salt spray testing.

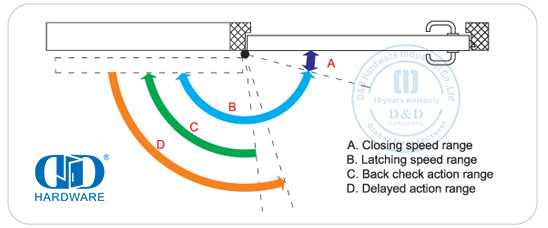

Modern hydraulic closers offer a range of adjustable features to tailor performance to specific needs:

-Closing Speed: Controls the main swing speed of the door from fully open to approximately 15 degrees.

-Latching Speed: A separate adjustment for the final 15 degrees to ensure positive latching without slamming.

-Backcheck: A hydraulic cushion that engages when the door is opened forcefully (usually beyond 70 degrees), protecting the door, closer, and surrounding walls from damage.

-Delayed Action: Holds the door open for a few seconds after opening (typically between 70-85 degrees) before initiating the closing cycle, aiding accessibility for people with mobility aids.

Do not compromise on quality. A superior hydraulic door closer is defined by:

-Precision Engineering: High-quality internal valves and seals that prevent oil leakage—the most common cause of closer failure.

-Robust Construction: A body made of high-tensile aluminum or steel with a corrosion-resistant finish.

-Independent Certification: Look for verifiable marks like the CE mark (with supporting DoP) or UL Listing (with file number). These are your assurance that the product has been independently tested to perform as claimed.

While budget is always a consideration, the true cost of a door closer includes its lifespan and maintenance requirements. A cheaper, uncertified model may save money initially but is likely to fail prematurely, leading to costly repairs, safety liabilities, and replacement. Investing in a high-quality, certified closer from a reputable manufacturer like D&D ensures decades of reliable, safe, and maintenance-free operation, providing superior long-term value.

By systematically evaluating these eight factors—door specifications, fire rating, traffic, installation, environment, functions, quality, and total cost of ownership—you can make an informed and confident decision. The right hydraulic door closer is an investment that delivers seamless operation, enhanced safety, and enduring performance, perfectly tailored to the demands of your building and its occupants.

For More details about door closer, pls feel free to contact us!

Contact :David Jian

Mobile:+86 - 139 2903 7292

E-mail: sales@danddhardware.com