Get Famous Branded Quality at Factory Cost

Pls inquire to sales@danddhardware.com

\\: +86 139 2903 7292

Author: Site Editor Publish Time: 2025-11-12 Origin: Site

A properly functioning door closer is a small but critical component for any commercial building. It ensures doors close securely behind people, maintaining building security, controlling access, and enhancing fire safety. It also prevents doors from slamming, which protects the door frame and reduces noise. While calling a professional is always an option, installing a commercial door closer is a manageable task if you have the right tools and instructions.

This guide will walk you through the entire process, from selecting the right closer to making final adjustments. By following these steps, you can ensure your door operates smoothly and safely, providing peace of mind for you, your employees, and your customers. We’ll cover the different installation types, the tools you'll need, and a detailed, step-by-step process for a successful installation.

Before you start unscrewing anything, it's essential to gather your tools and understand the components you'll be working with. A little preparation goes a long way in making the installation process smooth and efficient.

Having the right tools on hand will prevent delays and frustration. Here’s what you’ll typically need:

· Safety Glasses: Always protect your eyes from dust and debris.

· Drill and Drill Bits: A power drill is necessary for creating pilot holes for the mounting screws. Ensure you have a set of bits suitable for the material of your door and frame (wood, metal, or masonry).

· Screwdriver or Screw Gun: You'll need this to fasten the closer body and arms to the door and frame. A Phillips head is most common, but check the screws provided with your closer.

· Tape Measure: Accurate measurements are crucial for placing the closer correctly.

· Level: A level ensures the closer body is mounted straight, which is important for its proper function.

· Pencil or Marker: For marking the drilling locations.

· Wrench: An adjustable wrench is needed for tightening nuts and making adjustments to the closer arms.

Your new commercial door closer kit will come with several components. Familiarize yourself with them before you start:

· Closer Body: The main hydraulic mechanism that controls the door's closing speed.

· Main Arm: Connects the closer body to the forearm.

· Forearm: Attaches to the door frame (or door, depending on the installation type) and connects to the main arm.

· Mounting Template: A paper guide that shows you exactly where to drill holes for your specific installation. This is your most important tool.

· Screws and Fasteners: The kit will include all the necessary screws for mounting the closer.

· Adjustment Valves: Small screws on the closer body that control the closing and latching speed.

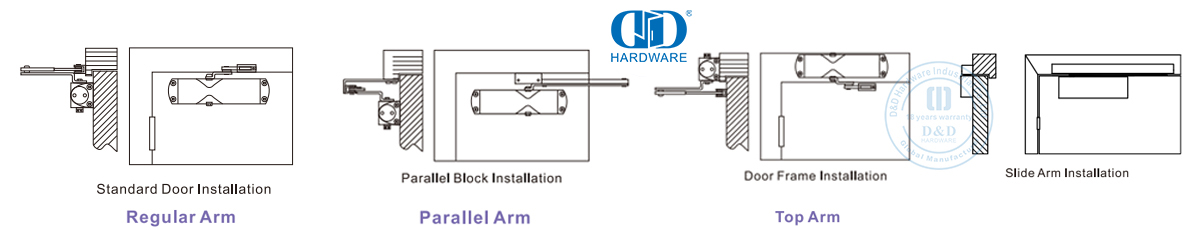

Commercial door closers can be installed in three primary ways. The best method depends on your door, the frame, and whether the door opens inward or outward. Your installation template will have diagrams for all three options.

This is the most common and efficient installation method.

· Closer Body Location: Mounted on the pull side (the side you pull to open) of the door.

· Arm Location: The arm assembly is mounted to the door frame.

· Best for: Interior doors that open inward. It provides the most power and control.

This method is used when the door frame is too narrow for a standard installation.

· Closer Body Location: Mounted on the top jamb (the horizontal part of the frame) on the push side of the door.

· Arm Location: The arm is mounted directly onto the door.

· Best for: Outward-opening doors, such as exterior or storefront doors, especially those with glass or narrow aluminum frames.

This is a more aesthetically pleasing option for push-side installations, as it keeps the arms parallel to the door when closed.

· Closer Body Location: Mounted on the push side of the door.

· Arm Location: A special bracket is used to mount the forearm parallel to the door frame.

· Best for: High-traffic areas or where vandalism is a concern, as the arms are less obtrusive. It's common in schools and public buildings.

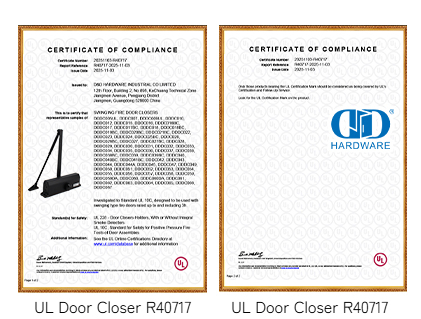

D&D Fire Rated Door Closer :

CE Door Closer - BS EN1154 500,000 cycles test, EN1634 Fire Rated 120/180mins, EN1670 Corrosion Resistance 96 hours.

UL Door Closer - UL Listed, UL 10C Fire Rated 3 Hours, UL File No.R40717

Once you've chosen your installation method and gathered your tools, you're ready to begin. We'll use the standard installation as our primary example, but the steps are similar for all three types—just follow the correct diagram on your template.

This is the most critical step. Take the paper template from the box and fold or cut it along the dotted line corresponding to your chosen installation type.

Place the template against the top edge of the door and the edge of the door jamb on the hinge side. Use tape to hold it securely in place. The template will indicate the exact locations for drilling holes for both the closer body on the door and the arm bracket on the frame.

Using a pencil or a center punch, mark the center of each screw hole indicated on the template. Be precise. Once all the points are marked, remove the template.

Select a drill bit that is slightly smaller than the diameter of the provided screws. This will create a pilot hole that allows the screws to grip the material firmly without splitting it. Carefully drill pilot holes at each marked location on both the door and the frame.

Position the closer body on the door, aligning its mounting holes with the pilot holes you just drilled. Use the provided screws to securely fasten the body to the door. Use your level to double-check that the closer is perfectly horizontal before fully tightening the screws. An unlevel closer will not function correctly and may leak hydraulic fluid over time.

First, attach the forearm bracket to the door frame using the provided screws.

Next, you’ll need to connect the main arm to the closer body. The arm attaches to a square shaft (the pinion shaft) on top of the closer. The instructions will specify the correct orientation. In a standard installation, the arm should be angled away from the hinge side of the door. Attach the arm using the supplied washer and screw, and tighten it with a wrench.

Now, connect the two arms. The forearm is adjustable in length. Adjust it so that it connects to the main arm at a 90-degree angle to the door frame when the door is closed. This angle is crucial for the closer to operate with the correct leverage and power. Use the provided screws and nuts to connect the two arms, but don't tighten them completely just yet.

Your commercial door closer has adjustment valves that control how fast the door closes. There are typically three main adjustments:

· Sweep Speed (Closing): This controls the speed of the door from fully open to about 10 degrees from the latch.

· Latch Speed: This controls the final few inches of closing, ensuring the door latches securely without slamming.

· Backcheck (Optional): This feature slows the door down if it's thrown open forcefully, preventing it from hitting an adjacent wall.

To make adjustments, use a small screwdriver or the tool provided. Turn the screws in small increments (no more than a quarter turn at a time).

· Clockwise: Slows the speed.

· Counter-clockwise: Increases the speed.

Open the door and let it close, observing the speed. Adjust the sweep and latch valves until you achieve a smooth, controlled close. A good rule of thumb is for the door to take about 5-7 seconds to close from 90 degrees.

Once you are satisfied with the closing speed, fully tighten all the screws connecting the arm assembly. Manually open and close the door a few times to ensure everything moves smoothly without binding.

Finally, place the decorative plastic or metal cover over the closer body. It should snap or slide into place, giving the installation a clean, finished look.

Installing a commercial door closer can seem intimidating, but by following the template and these instructions, it's a project well within reach. Taking the time to do it right ensures your door will operate reliably, enhancing the safety and professionalism of your establishment. Remember to check the closer's performance periodically, as temperature changes can affect the hydraulic fluid and may require minor speed adjustments.

With your new closer installed, you can be confident that your doors are secure, accessible, and ready for business.

Click here for additional details on door closers.

Now contact us.

Contact information for David Jian

Contact number: 0086-139 2903 7292

Email address: sales@danddhardware.com