Get Famous Branded Quality at Factory Cost

Pls inquire to sales@danddhardware.com

\\: +86 139 2903 7292

Author: Site Editor Publish Time: 2026-01-08 Origin: Site

Have you ever walked up to a building and noticed orange streaks running down the door frame? It’s an immediate eyesore. Rusty hinges aren't just a cosmetic issue; they are a sign of degradation that can lead to squeaky operation, sticking doors, and eventually, structural failure.

For property managers and homeowners alike, maintaining the integrity of exterior door hinges is crucial. Whether you are maintaining a coastal home or specifying a door hinge for Public Building projects, battling rust is a top priority. Moisture, salt air, and pollution all work together to corrode metal. However, with the right materials and a consistent maintenance schedule, you can keep your entrances looking professional and functioning smoothly for years to come.

Rust occurs when iron reacts with oxygen and moisture. This oxidation process is accelerated in certain environments. For example, a door hinge for office building entrances located near the ocean will deteriorate much faster than one in a dry, inland climate due to the salt content in the air.

Standard steel hinges are strong, but without proper protection, they are highly susceptible to rust. Even plated finishes (like brass-plated steel) can eventually wear down, exposing the raw steel beneath to the elements. Once that barrier is breached, corrosion begins almost immediately.

The most effective way to prevent rust is to choose the right base material from the start. While aesthetics are important, the material composition dictates the longevity of the hardware.

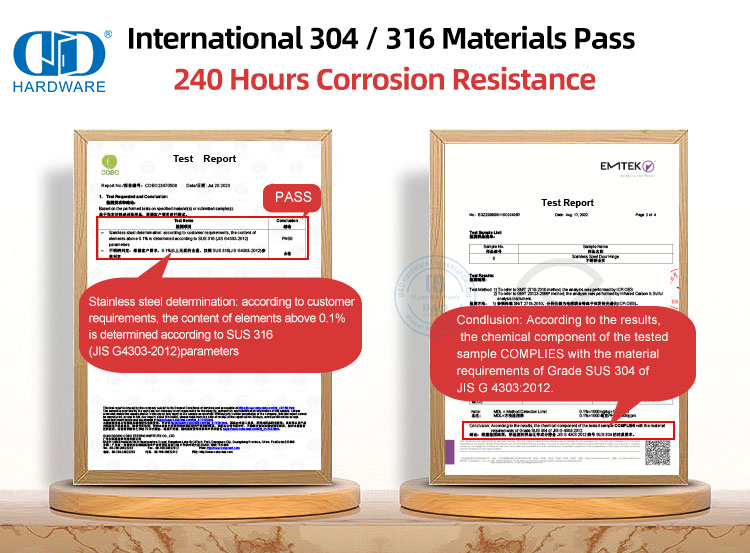

Stainless Steel is the gold standard for exterior use. Unlike surface-plated options, stainless steel is corrosion-resistant all the way through.

Grade 304 Stainless Steel: This is the standard for most exterior applications. It offers excellent resistance to corrosion and is suitable for most residential and commercial buildings.

Grade 316 Stainless Steel: Often called "marine grade," this alloy contains molybdenum, which drastically increases corrosion resistance. This is the ideal choice for coastal properties or industrial environments with high chemical exposure.

When selecting hardware for high-traffic areas, such as a door hinge for office building or school, investing in high-quality stainless steel ensures the door operates safely and looks clean despite heavy usage and weather exposure.

To help you choose the right hinge for your project, refer to the table below comparing common hinge materials:

Material | Rust Resistance | Durability | Best Application |

|---|---|---|---|

Stainless Steel (304/316) | Excellent | High | Exterior doors, coastal areas, public buildings |

Solid Brass | High (Does not rust, but tarnishes) | Medium | Decorative exterior doors, residential |

Plated Steel | Low to Medium | High | Interior doors, dry environments |

Aluminum | High | Low to Medium | Lightweight doors, specific storefronts |

Even the highest quality exterior door hinges benefit from regular care. A simple maintenance routine can extend the lifespan of your hardware significantly.

Clean Regularly: Dirt and grime can trap moisture against the metal. Wipe down hinges with a mild soap and water solution, then dry them thoroughly. Avoid harsh chemicals that could strip protective coatings.

Inspect for Damage: Check for scratches or chips in the finish. For commercial settings like a door hinge for Public Building entrance, catch these issues early before rust spreads.

Lubricate: Apply a high-quality lubricant (like white lithium grease or a silicone-based spray) to the hinge pin and knuckles. This prevents friction, which can wear down the metal and invite corrosion. Avoid standard WD-40 for long-term lubrication, as it can attract dirt.

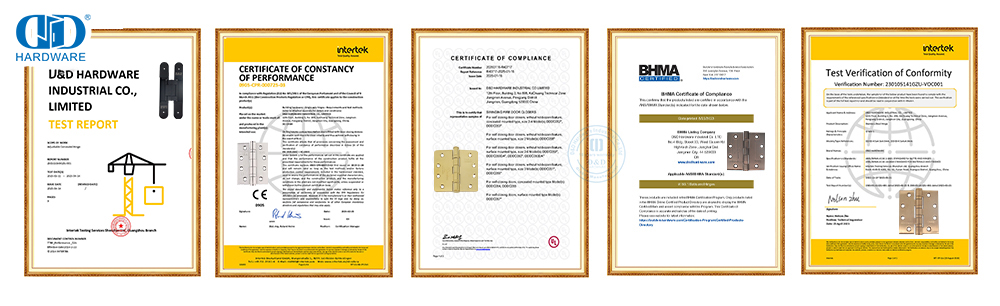

Yes, absolutely. When selecting hardware, look for industry certifications such as ANSI/BHMA or UL listings.

Manufacturers like D&D Hardware Industrial Co., Ltd. produce hinges that undergo rigorous testing for cycle usage and fire safety. An ANSI Grade 1 hinge, for instance, is built to withstand rigorous use and harsh conditions better than a standard residential hinge. Using certified hardware ensures that the base materials and manufacturing processes meet strict quality standards, providing you with a product that is less likely to fail or corrode prematurely.

️✔ CE Door Hinge - BS EN1935 200,000 cycles test, EN1634 Fire Rated 192mins/260mins, EN1670 Corrosion Resistance 240 hours.

️✔ UL Door Hinge - UL/cUL Listed, UL 10C Fire Rated 3 Hours, File No.R38013

✔ BHMA Door Hinge - ANSI/BHMA 156.1 and ANSI/BHMA 156.18

✔ ANSI Door Hinge - ANSI Grade 1 2,500,000 cycles test, ANSI Grade 2 1,500,000 cycles test

✔ CE Concealed Hinge-BS EN1935 200,000 cycles test, EN1634 Fire Rated 132mins, EN1670 Corrosion Resistance 48 hours.

Preventing rust starts with selection and ends with maintenance. By choosing the right stainless steel grade for your environment and keeping the hardware clean, you protect your investment and ensure safe, smooth operation.

Whether you need a heavy-duty door hinge for office building use or reliable exterior door hinges for a home, prioritizing quality materials is the key to longevity. Don't let rust compromise your building's safety or curb appeal—upgrade to corrosion-resistant solutions today.

For high-quality, certified door hardware solutions, consider exploring the extensive range at D&D Hardware.

Click here for additional details on door hinges.

Now contact us.

Contact information for David Jian

Contact number: 0086-139 2903 7292

Email address: sales@danddhardware.com