Get Famous Branded Quality at Factory Cost

Pls inquire to sales@danddhardware.com

\\: +86 139 2903 7292

Author: Site Editor Publish Time: 2025-11-11 Origin: Site

A commercial door that slams shut isn't just an annoyance; it's a safety hazard and a sign that something needs attention. Conversely, a door that closes too slowly can compromise security and hike up your energy bills. The culprit in both scenarios is often a misaligned commercial door closer.

Learning how to adjust a commercial door closer is a valuable skill for any property manager or business owner. It allows you to fine-tune your entryway's performance, ensuring it operates safely, securely, and efficiently. This guide will walk you through the entire process, explaining what each adjustment valve does and how to get that perfect, smooth close every time. With a few simple tools and a bit of patience, you can extend the life of your door hardware and create a better experience for everyone entering your building.

A commercial door closer is a mechanical device installed at the top of a door and its frame. Its primary function is to control the door's closing cycle, ensuring it shuts automatically and in a controlled manner after someone opens it.

These devices use a spring-loaded hydraulic system. When you open the door, you compress a powerful internal spring while forcing hydraulic fluid from one chamber to another. When you let go, the spring's tension pushes the door closed, and the hydraulic fluid flows back through a series of valves. The speed and force of this closing action are managed by adjusting these valves.

Commercial door closers are built to withstand heavy, repeated use, making them a standard feature in high-traffic areas like retail stores, offices, schools, and hospitals.

D&D Fire Rated Commercial Door Closer :

CE Door Closer - BS EN1154 500,000 cycles test, EN1634 Fire Rated 120/180mins, EN1670 Corrosion Resistance 96 hours.

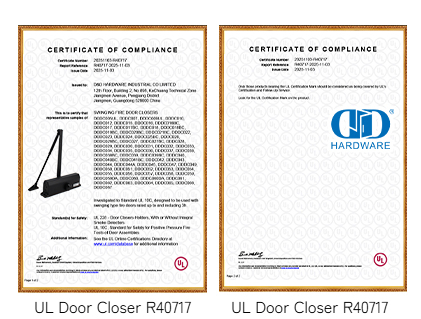

UL Door Closer - UL Listed, UL 10C Fire Rated 3 Hours, UL File No.R40717

Before you start turning screws, it’s helpful to diagnose the specific issue with your door. Here are some of the most common problems you'll encounter:

· Door Slams Shut: The door closes too quickly, creating a loud noise and posing a risk of injury. This is usually caused by a misadjusted swing speed or latch speed.

· Door Closes Too Slowly: The door takes too long to close, which can be a security risk and affect your building's climate control. This might also indicate a loss of hydraulic fluid or a weak spring.

· Door Doesn't Latch Properly: The door closes almost all the way but fails to click securely into the frame. This leaves the door unlocked and ajar.

· Door is Hard to Open: The door offers excessive resistance, making it difficult for people, especially children or those with disabilities, to open it. This points to a backcheck or spring power setting that is too high.

· Visible Fluid Leak: You can see oil stains on the closer's body, on the door, or dripping onto the floor. This is a serious issue indicating a seal failure, and the unit will likely need to be replaced.

Adjusting a commercial door closer doesn't require a full toolbox. In most cases, you'll only need one or two of the following:

· A flathead screwdriver

· An Allen wrench (hex key)

· A stepladder

Make sure you have a stable ladder to safely reach the door closer. It's also a good idea to have the manufacturer's instruction manual handy if possible, as valve locations can vary slightly between brands.

Most commercial door closers have a set of small, labeled screws that control different phases of the closing cycle. These are typically found on the body of the closer. The labels are often abbreviated, such as "S" for Swing Speed, "L" for Latch Speed, and "BC" for Backcheck.

Important: When making adjustments, turn the screws in small increments—no more than a quarter-turn at a time. A small turn can have a significant effect on the door's speed.

The swing speed (or sweep speed) controls how fast the door closes from its fully open position to the last few inches before it shuts.

· To slow the door down: Turn the "S" screw clockwise.

· To speed the door up: Turn the "S" screw counter-clockwise.

Open the door fully and let it close. Observe the speed and make small adjustments until it closes at a controlled, safe pace. A typical swing should take about 5–7 seconds.

The latch speed controls the final 10-15 degrees of the closing arc. This is the part of the cycle where the door clicks into the latch.

· To slow the latching: Turn the "L" screw clockwise.

· To speed up the latching: Turn the "L" screw counter-clockwise.

If your door is slamming shut only at the very end, you need to slow down the latch speed. If it isn't closing firmly enough to latch, you'll need to increase the speed slightly.

Backcheck is a feature that provides resistance when the door is opened forcefully or beyond a certain angle (usually around 75 degrees). It acts as a cushion to prevent the door from slamming into an adjacent wall and protects the closer itself from damage.

· To increase resistance: Turn the "BC" screw clockwise.

· To decrease resistance: Turn the "BC" screw counter-clockwise.

If your door is hitting a wall when opened with force, increase the backcheck. If the door feels very heavy and difficult to open past a certain point, decrease the backcheck.

Some commercial door closers have an adjustable spring, which controls the overall force or "size" of the closer. This adjustment is less common for routine maintenance and is often set during installation. The adjustment is usually a large nut at one end of the closer body.

· To increase closing force: Turn the adjustment nut clockwise. This makes the door harder to open but gives it more power to close against drafts or internal air pressure.

· To decrease closing force: Turn the adjustment nut counter-clockwise. This makes the door easier to open.

Adjusting the spring power should be done carefully, as it significantly impacts all other settings. Only change this if the door is extremely difficult to open or fails to close completely despite other adjustments.

While many issues can be fixed with simple adjustments, some problems signal that your commercial door closer has reached the end of its life. You should call a professional locksmith or door hardware specialist if you notice:

· Fluid Leaking: If you see any hydraulic fluid, the closer's internal seals have failed. The unit cannot be repaired and must be replaced. Do not overtighten the valves, as this can cause seal damage.

· Screws Don't Respond: If turning the adjustment screws has no effect on the door's speed, the valves may be clogged or damaged internally.

· The Closer is Visibly Damaged: Cracks in the housing, a bent arm, or other visible damage are clear signs that a replacement is needed.

Properly adjusting your commercial door closer is an essential part of building maintenance. It ensures your doors are safe, secure, and compliant with accessibility standards. By following these steps, you can confidently fine-tune your door's performance and address common issues before they become major problems.

If you find that your door closer is beyond repair or if you're looking to upgrade your hardware, explore a range of high-quality commercial door closers that can meet the demands of any entryway.

Click here for additional details on door closers.

Now contact us.

Contact information for David Jian

Contact number: 0086-139 2903 7292

Email address: sales@danddhardware.com