Get Famous Branded Quality at Factory Cost

Pls inquire to sales@danddhardware.com

\\: +86 139 2903 7292

Author: Site Editor Publish Time: 2025-12-17 Origin: Site

In the realm of commercial and fire - rated door applications, 3D adjustable concealed door hinges play a crucial role. These hinges not only need to provide smooth and reliable movement for doors but also must endure the rigors of long - term use and withstand various environmental factors. To ensure that these hinges meet the necessary quality and performance standards, two key European standards—BS EN 1935 and EN 1670—are in place. These standards serve as benchmarks for determining whether a hinge is suitable for demanding building conditions.

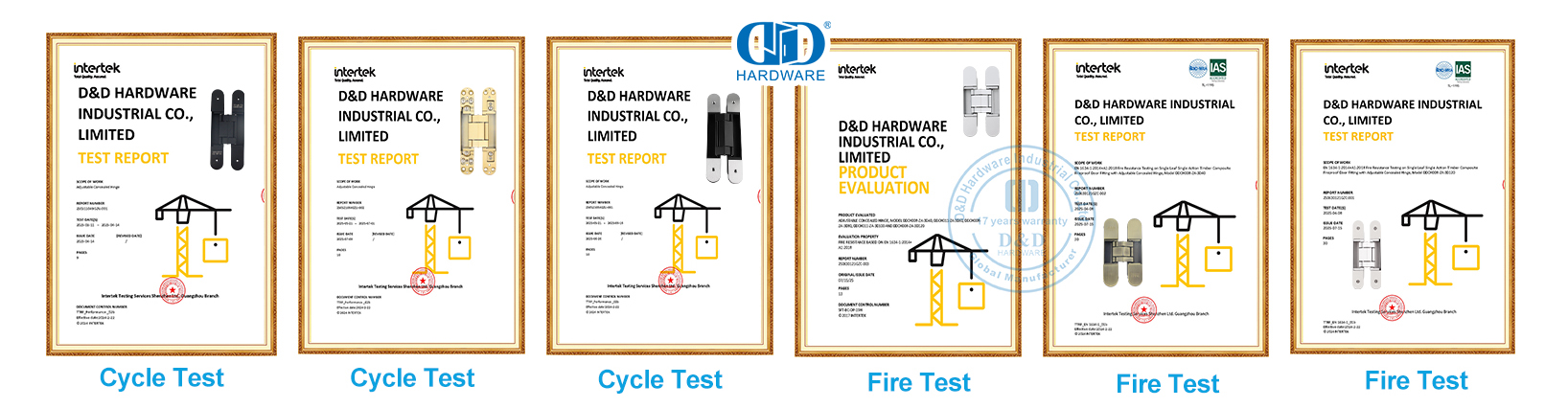

D&D concealed door hinge - BS EN1935 200,000 cycles test, EN1634 fire rated 132mins, EN1670 corrosion resistance 48 hours

BS EN 1935 is the preeminent European standard that governs single - axis hinges for doors, encompassing concealed hinges as well. The 200,000 cycles test within this standard is designed to simulate heavy - duty usage scenarios, effectively replicating years of repeated door opening and closing under load.

During the testing procedure, the hinge is put through a rigorous series of continuous opening and closing cycles. Each cycle is precisely controlled to mimic real - world door movements. The test also takes into account defined door mass and torque. The door mass is set to represent typical loads that a hinge would encounter in a commercial or fire - rated setting, while the torque is adjusted to simulate the force exerted on the hinge during door operation.

Throughout the 200,000 cycles, the hinge is closely monitored for several key factors. Deformation is one of the primary concerns. Even a slight change in the shape of the hinge components can affect its ability to function properly. Wear is another critical aspect; as the hinge moves repeatedly, the surfaces of its parts can start to wear down, leading to potential issues such as increased friction or loose connections. Functional failure is the most serious outcome, indicating that the hinge is no longer able to perform its basic task of allowing the door to open and close smoothly.

Passing the 200,000 cycles test is of paramount importance for a variety of applications. In commercial buildings, such as offices, shopping malls, and hotels, doors are opened and closed frequently throughout the day. A hinge that can withstand 200,000 cycles ensures that the doors will continue to operate reliably, reducing the need for frequent maintenance or replacement. Public facilities, like schools, hospitals, and libraries, also rely on durable hinges to handle the high volume of traffic. For fire doors, which are essential for safety in case of a fire, the hinge's ability to withstand intensive daily use without losing structural integrity is crucial. A malfunctioning hinge on a fire door could prevent it from closing properly, potentially allowing the spread of fire and smoke.

EN 1670 is focused on evaluating the corrosion resistance of door hardware, and it does so through a controlled salt spray test. A 48 - hour corrosion resistance rating is a significant indicator that the hinge's surface treatment and base materials are capable of resisting rust and degradation in mildly corrosive environments.

The salt spray test involves exposing the hinge to a fine mist of salt solution in a controlled chamber. The salt solution simulates the corrosive effects of environments that contain salt, such as coastal regions where the air is often laden with salt particles from the sea. The 48 - hour duration of the test is carefully chosen to provide a reasonable assessment of the hinge's ability to resist corrosion over time. During this period, the hinge is continuously exposed to the salt mist, and its surface is inspected for signs of rust, pitting, or other forms of degradation.

This test is particularly critical for a range of applications. In humid interiors, such as bathrooms, kitchens, and laundry rooms, the high moisture levels can accelerate the corrosion process. A hinge with good corrosion resistance will be able to withstand these conditions and continue to function properly.

Coastal regions, as mentioned earlier, are highly corrosive due to the salt in the air. Buildings in these areas, whether residential or commercial, require hinges that can resist the corrosive effects of the environment. Additionally, buildings that undergo frequent cleaning or are exposed to moisture, such as swimming pools, spas, and food processing facilities, also benefit from hinges with high corrosion resistance.

For concealed hinges, corrosion resistance is especially important. Since the internal components of concealed hinges are less visible once installed, it can be difficult to detect early signs of corrosion. If corrosion goes unnoticed, it can gradually damage the hinge, leading to functional problems and potentially requiring costly repairs or replacements.

When a 3D concealed hinge meets both BS EN 1935 (200,000 cycles) and EN 1670 (48 hours) standards, it offers a comprehensive solution that combines mechanical endurance and surface protection.

The combination of these two standards ensures that the hinge will perform consistently over time. The 200,000 cycles test guarantees that the hinge can handle the mechanical stresses of repeated use, while the 48 - hour corrosion resistance test ensures that it can withstand environmental factors that could otherwise degrade its performance. This means that the door will open and close smoothly, without any unexpected failures or malfunctions, regardless of the usage frequency or the environmental conditions.

By meeting these standards, the hinge reduces the risk of maintenance issues. A hinge that is durable and corrosion - resistant will require less frequent maintenance compared to one that does not meet these standards. This can save building owners and managers time and money, as they will not need to spend as much on hinge inspections, repairs, or replacements.

The combination of mechanical endurance and corrosion resistance also contributes to a longer service life for the hinge. A hinge that can withstand 200,000 cycles and resist corrosion for 48 hours is likely to last much longer than one that does not meet these standards. This extended service life means that the hinge can provide reliable performance for many years, reducing the need for premature replacements and contributing to the overall sustainability of the building.

These certifications provide specifiers and inspectors with objective proof that the hinge meets European expectations for durability and environmental resistance. Specifiers can confidently select hinges that meet these standards, knowing that they are choosing products that have been rigorously tested and proven to perform. Inspectors can also rely on these certifications to ensure that the hinges installed in buildings comply with the relevant regulations and standards, providing peace of mind for building owners and occupants.

In conclusion, BS EN 1935 and EN 1670 are two essential standards for 3D concealed door hinges in commercial and fire - rated applications. By understanding and adhering to these standards, manufacturers can produce high - quality hinges that offer long - term mechanical durability and environmental resistance, while specifiers and inspectors can ensure that the hinges installed in buildings meet the necessary performance requirements.

Click here for additional details on concealed door hinges.

Now contact us.

Contact information for David Jian

Contact number: 0086-139 2903 7292

Email address: sales@danddhardware.com