Get Famous Branded Quality at Factory Cost

Pls inquire to sales@danddhardware.com

\\: +86 139 2903 7292

You use them dozens of times every day, yet most people never stop to think about the clever engineering behind a simple door handle. From your bedroom to your office, these ubiquitous devices silently perform their job with remarkable reliability. But beneath their straightforward appearance lies a fascinating world of springs, levers, and mechanical principles that have been refined over centuries.

Understanding how a door handle works isn't just satisfying curiosity—it can help you troubleshoot problems, make better purchasing decisions, and appreciate the thoughtful design that goes into everyday objects. Whether you're dealing with a sticky handle or simply want to understand the mechanics of your home's hardware, this guide will walk you through everything you need to know.

Every door handle system consists of several key components that work together to create a smooth, secure operation. The handle itself is just the tip of the iceberg.

The door handle serves as the primary interface between you and the locking mechanism. Most modern handles use a lever system, which provides mechanical advantage—meaning a small force applied to the handle creates a larger force at the latch mechanism. This lever action makes it easy to open doors even when your hands are full or when the latch mechanism has some resistance.

Running through the center of the door handle assembly is a square metal rod called a spindle. When you turn the handle, this spindle rotates, transferring the motion from the handle on one side of the door to the latch mechanism inside the door. The spindle must be precisely sized to fit snugly within the handle mechanism while allowing smooth rotation.

Hidden inside the door's edge is the latch assembly, which contains the actual locking mechanism. This typically includes a spring-loaded latch bolt that extends into the door frame to keep the door closed, along with various springs and levers that control its movement.

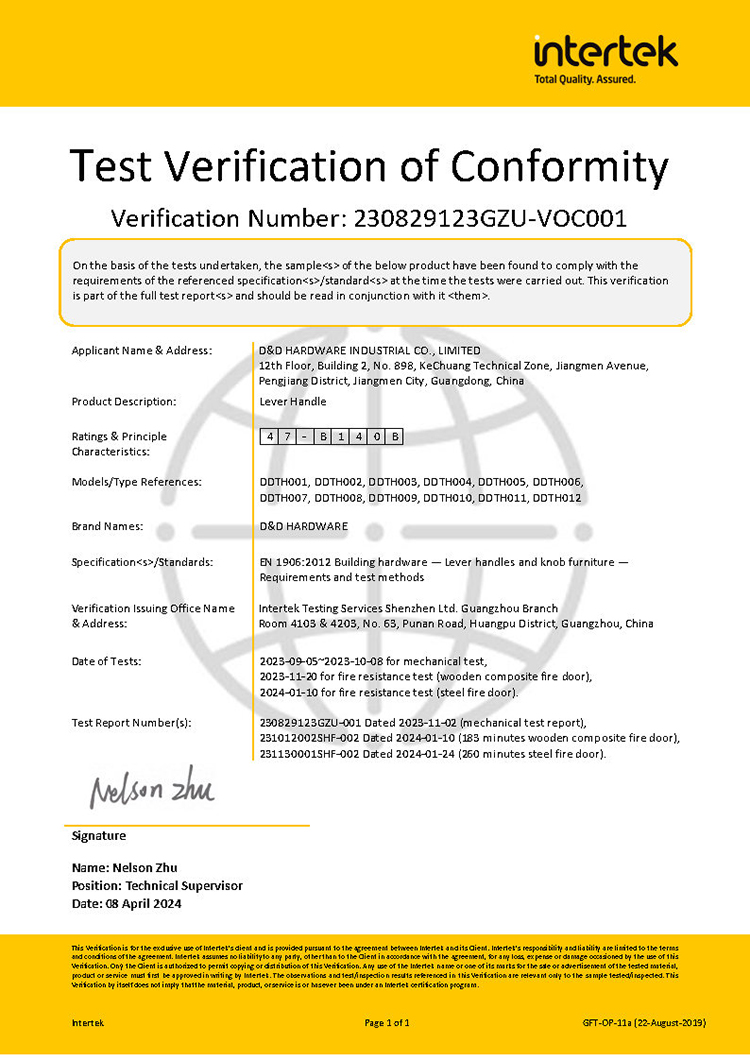

D&D BS EN Door Handle: BS EN1906 300,000 cycles test, EN1634 Fire Rated 183/260mins, EN1670 Corrosion Resistance 240 hours.

Understanding how a door handle works becomes clearer when you break down the process into individual steps.

When you press down on a lever-style handle or turn a knob, you're applying rotational force (called torque) to the spindle. The handle's design amplifies this force through leverage, similar to how a wrench makes it easier to turn a bolt.

As the handle rotates, it turns the spindle, which passes through the door and connects to the latch mechanism on the other side. This spindle acts as a direct mechanical link between your hand movement and the internal locking components.

The rotating spindle engages with a cam or lever inside the latch assembly. This component converts the rotational motion of the spindle into linear motion, pulling the latch bolt back into the door and away from the door frame.

With the latch bolt retracted, the door is free to swing open. The entire process happens almost instantaneously, thanks to the direct mechanical connection between all components.

When you release the handle, springs within both the handle mechanism and the latch assembly return everything to its original position. The latch bolt extends back into the door frame, and the handle returns to its neutral position.

Not all door handles work exactly the same way. The basic principles remain consistent, but different styles have unique characteristics.

Lever handles are the most common type in modern construction. They operate on a simple pivot mechanism and are particularly useful for accessibility, as they can be operated with an elbow or forearm when hands aren't available. The lever design provides excellent mechanical advantage, making them easy to operate even for people with limited hand strength.

Traditional door knobs require a twisting motion rather than a pressing motion. The internal mechanism is similar to lever handles, but the user interface requires grasping and rotating the entire knob. While less accessible than levers, knobs have a classic aesthetic appeal and work well in many applications.

Some doors use simple push or pull handles that don't involve any turning mechanism. These are typically found on doors that don't latch automatically, such as some commercial or industrial applications. The handle provides grip and leverage for opening the door, but there's no complex internal mechanism.

Springs play a crucial role in door handle functionality, though they're often overlooked. These components ensure that the system returns to its proper position after each use.

The handle return spring keeps the handle in its neutral position when not in use. Without this spring, handles would flop around loosely and wouldn't provide the tactile feedback users expect. The latch spring keeps the latch bolt extended into the door frame, ensuring the door stays closed until intentionally opened.

These springs must be calibrated carefully. Too weak, and the mechanism won't return properly. Too strong, and the handle becomes difficult to operate. Quality door handle manufacturers spend considerable effort getting this balance right.

Understanding how door handles work helps explain why certain problems occur and how to address them.

When a door handle becomes difficult to operate, the problem usually lies in one of several areas. The spindle might be binding within its housing due to dirt or corrosion. The latch mechanism could be sticking due to paint buildup or debris. Sometimes, the door frame has shifted slightly, causing the latch bolt to bind against the strike plate.

Handle looseness typically results from worn screws or mounting hardware. Since the handle experiences repeated stress from daily use, these connection points can gradually loosen. The spindle might also become worn where it connects to the handle or latch mechanism.

When handles fail to return to their neutral position, spring problems are usually the culprit. The return springs may have weakened over time, broken entirely, or become disconnected from their mounting points.

Knowing how door handles work can help you make better decisions when selecting new hardware. Consider the frequency of use, the users who will operate the handles, and the specific requirements of each location.

High-traffic areas benefit from robust mechanisms with strong springs and durable materials. Accessibility requirements might dictate lever-style handles over knobs. Security needs could influence your choice of latch mechanisms and handle styles.

Understanding the mechanical principles also helps you appreciate quality differences between products. Well-engineered handles will have smooth operation, appropriate spring tension, and durable materials that resist wear over time.

Door handles represent a perfect example of elegant engineering—simple in concept but sophisticated in execution. The next time you grasp a handle and effortlessly open a door, you'll have a deeper appreciation for the mechanical symphony happening in your palm. From the leverage multiplication of the handle itself to the precise spring tensions that govern its operation, these everyday devices showcase centuries of refinement in mechanical design.

Whether you're troubleshooting a problematic handle, selecting new hardware, or simply satisfying your curiosity about the world around you, understanding these mechanisms connects you to the thoughtful engineering that shapes our daily experiences.

Click here for additional details on door handles.

Now contact us.

Contact information for David Jian

Contact number: 0086-139 2903 7292

Email address: sales@danddhardware.com