Get Famous Branded Quality at Factory Cost

Pls inquire to sales@danddhardware.com

\\: +86 139 2903 7292

Author: Site Editor Publish Time: 2025-07-29 Origin: Site

Selecting the right door handle involves more than just aesthetics and budget considerations. For projects requiring durability and longevity, understanding the difference between EN 1906 Grade 4 and Grade 3 stainless steel door handles can make or break your installation's long-term performance.

The EN 1906 standard establishes clear performance criteria for door handles, with Grade 4 representing the highest level of durability and Grade 3 offering excellent performance for most applications. This classification system helps architects, contractors, and facility managers make informed decisions based on expected usage patterns, environmental conditions, and project requirements.

Making the wrong choice can lead to premature hardware failure, increased maintenance costs, and potential safety concerns. This guide examines the key differences between these grades, helping you determine which stainless steel door handle specification best serves your specific project needs.

The EN 1906 European standard classifies door handle performance across four grades, with Grade 4 representing the most demanding applications and Grade 1 suitable for light residential use. This classification system evaluates handles based on durability, corrosion resistance, and operational performance under various stress conditions.

Grade classifications consider multiple performance factors including cycle testing, load testing, and environmental resistance. Manufacturers must demonstrate that their products can withstand specific numbers of operational cycles and loading conditions to achieve each grade designation.

Testing procedures simulate real-world usage patterns over extended periods. Grade 4 handles must endure 2 million operational cycles, while Grade 3 handles are tested to 1 million cycles. These tests involve repeated opening and closing operations under controlled conditions that replicate normal usage patterns.

Environmental testing ensures that handles maintain their performance characteristics when exposed to temperature variations, humidity changes, and corrosive conditions. Higher grades demonstrate superior resistance to these environmental stressors.

Grade 4 stainless steel door handles represent the pinnacle of commercial door hardware performance. These handles must withstand 2 million operational cycles during testing, making them suitable for the most demanding commercial and institutional applications.

Load testing requirements for Grade 4 handles exceed those of lower grades significantly. These handles must support axial loads up to 1,500 Newtons and radial loads up to 1,000 Newtons without failure or permanent deformation.

Corrosion resistance testing for Grade 4 handles involves extended exposure to salt spray and other corrosive environments. These handles must maintain their structural integrity and appearance even after prolonged exposure to harsh conditions commonly found in coastal areas or industrial environments.

Fire safety performance often distinguishes Grade 4 handles from lower grades. Many Grade 4 stainless steel door handles can be incorporated into fire-rated door assemblies, maintaining their performance characteristics even when exposed to high temperatures during fire conditions.

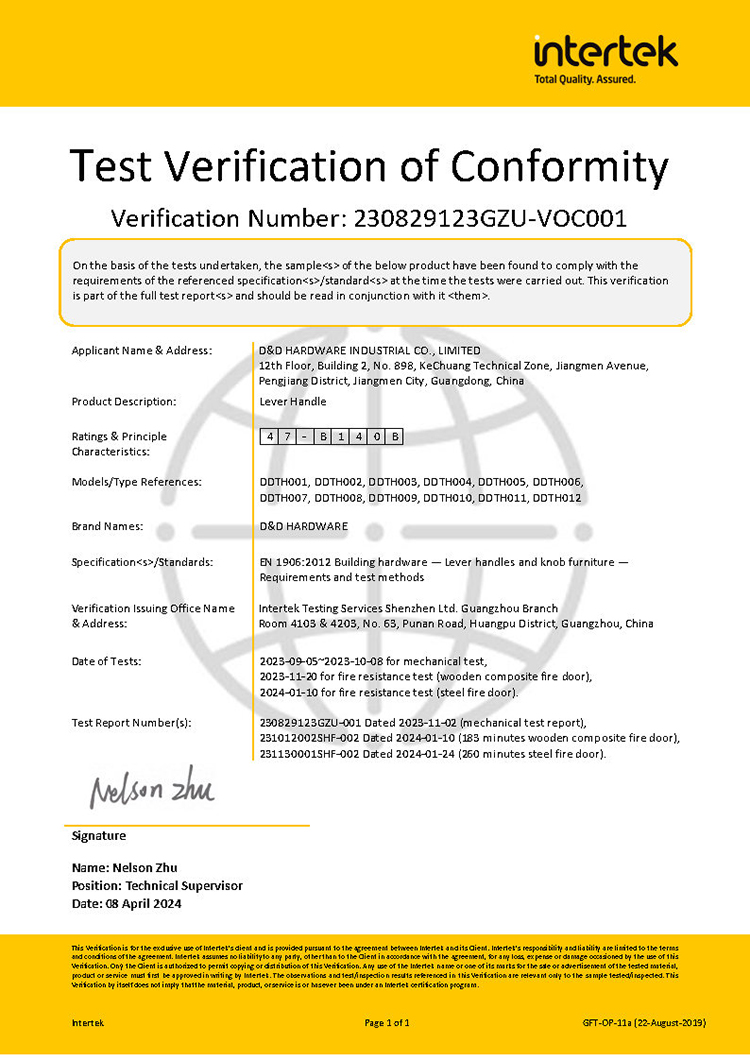

D&D BS EN Door Handle: BS EN1906 300,000 cycles test, EN1634 Fire Rated 183/260mins, EN1670 Corrosion Resistance 240 hours.

Grade 3 stainless steel door handles offer excellent performance for most commercial applications while providing cost advantages over Grade 4 specifications. These handles must complete 1 million operational cycles during testing, suitable for moderate to high-traffic applications.

Load requirements for Grade 3 handles include axial loads up to 1,200 Newtons and radial loads up to 750 Newtons. While lower than Grade 4 specifications, these requirements exceed the demands of most standard commercial applications.

Environmental resistance testing for Grade 3 handles demonstrates reliable performance under normal commercial conditions. These handles resist corrosion and maintain their appearance in typical indoor environments and moderate outdoor exposures.

Grade 3 handles often incorporate the same high-quality stainless steel materials as Grade 4 products but may use different manufacturing processes or design approaches that affect their ultimate performance capabilities under extreme conditions.

High-traffic commercial environments benefit significantly from Grade 4 stainless steel door handles. Office buildings, shopping centers, and transportation facilities experience constant door operation that can quickly exceed the capabilities of lower-grade hardware.

Educational facilities present unique challenges due to heavy usage patterns and potential misuse. Grade 4 handles in schools and universities provide the durability needed to withstand both high-frequency use and occasional abuse from students.

Healthcare facilities require door handles that can withstand frequent cleaning with harsh disinfectants while maintaining reliable operation. Grade 4 stainless steel handles resist chemical degradation better than lower grades, making them ideal for hospitals and medical offices.

Grade 3 handles work well in moderate-traffic commercial applications such as professional offices, retail stores, and light industrial facilities. These environments typically don't generate the extreme usage patterns that necessitate Grade 4 performance.

Industrial facilities often subject door hardware to extreme conditions including temperature variations, chemical exposure, and heavy usage. Grade 4 stainless steel door handles provide the durability needed for manufacturing plants, warehouses, and processing facilities.

Correctional facilities require hardware that can withstand both heavy use and potential vandalism attempts. Grade 4 handles offer superior resistance to tampering while maintaining reliable operation under institutional security requirements.

Food processing and pharmaceutical facilities need door hardware that can withstand frequent washdowns with cleaning chemicals and high-pressure water. Grade 4 stainless steel handles maintain their performance and appearance even under these demanding sanitation requirements.

Government buildings and military facilities often specify Grade 4 handles due to security considerations and the need for long-term reliability. These applications justify the additional cost through reduced maintenance requirements and extended service life.

Initial costs for Grade 4 stainless steel door handles typically exceed Grade 3 options by 20-40 percent, but this premium often proves justified through reduced lifecycle costs. Higher-grade handles require less frequent replacement and maintenance, offsetting their initial cost premium.

Labor costs for handle replacement can exceed the hardware costs in commercial applications. Grade 4 handles reduce replacement frequency, minimizing both material costs and labor disruptions over the building's operational life.

Warranty coverage often differs between grades, with Grade 4 handles frequently carrying longer warranty periods. Extended warranties reduce the owner's risk and provide additional value that helps justify the initial cost premium.

Energy efficiency considerations may favor higher-grade handles in climate-controlled environments. Better sealing characteristics and more precise manufacturing tolerances can reduce air infiltration around doors, contributing to HVAC efficiency.

Both Grade 3 and Grade 4 stainless steel door handles require proper installation to achieve their rated performance levels. Installation must follow manufacturer specifications exactly, with particular attention to mounting torques and alignment requirements.

Regular maintenance schedules help both grades achieve their expected service lives. Grade 4 handles may require less frequent adjustment and lubrication due to their superior manufacturing tolerances and materials.

Cleaning protocols should account for the handle's intended application and environmental exposure. Harsh cleaning agents that might be acceptable for Grade 4 handles could potentially damage Grade 3 hardware over time.

Replacement parts availability often favors Grade 4 handles from major manufacturers. Higher-end products typically enjoy longer production runs and better parts support, simplifying long-term maintenance planning.

Project-specific factors should drive the decision between Grade 3 and Grade 4 stainless steel door handles. High-traffic applications, harsh environments, and critical security requirements generally justify the Grade 4 premium.

Budget considerations must balance initial costs against lifecycle expenses. While Grade 3 handles cost less initially, Grade 4 handles may provide better long-term value in demanding applications through reduced maintenance and replacement costs.

Building codes and specifications may mandate specific performance grades for certain applications. Fire-rated assemblies and high-security installations often require Grade 4 hardware to meet regulatory requirements.

Consultation with hardware specialists helps ensure proper grade selection for complex projects. Professional evaluation of usage patterns, environmental conditions, and performance requirements guides optimal hardware selection.

The choice between EN 1906 Grade 4 and Grade 3 stainless steel door handles depends on careful evaluation of application requirements, usage patterns, and long-term costs. Grade 4 handles excel in demanding environments where durability and reliability are paramount, while Grade 3 handles provide excellent performance for most standard commercial applications.

Understanding these performance differences enables informed decision-making that balances initial costs with long-term value. The right choice protects your investment while ensuring reliable door operation throughout the building's service life.

Consider consulting with door hardware specialists who can evaluate your specific requirements and recommend the appropriate grade for each application. Professional guidance ensures that your door handle selection meets both current needs and future performance expectations.

Click here for additional details on door handles.

Now contact us.

Contact information for David Jian

Contact number: 0086-139 2903 7292

Email address: sales@danddhardware.com