Get Famous Branded Quality at Factory Cost

Pls inquire to sales@danddhardware.com

\\: +86 139 2903 7292

Author: Site Editor Publish Time: 2025-12-18 Origin: Site

If you are planning a renovation or simply need to replace a squeaky door, you might assume that a hinge is just a hinge. However, when it comes to the safety and functionality of your home, knowing the difference between interior and exterior hardware is crucial.

While they may look similar at a glance, exterior door hinges are engineered differently than their interior counterparts. They must withstand harsher weather conditions, support heavier door slabs, and most importantly, protect your home from intruders. Using the wrong type of hinge on an entry door isn't just a maintenance issue—it is a security risk.

In this guide, we will explore exactly how exterior hinges differ, the materials that make them durable, and how to choose the right one for your entryway.

The primary differences lie in security features, material composition, and load-bearing capacity.

Interior doors are typically hollow and lightweight, requiring standard hinges that focus on smooth movement rather than heavy-duty protection. Exterior doors, however, are solid, heavy, and exposed to the elements. Consequently, exterior door hinges are thicker, stronger, and often equipped with non-removable pins (NRP) to prevent someone from popping the door off from the outside.

Here is a quick comparison to help you visualize the differences:

Feature | Interior Door Hinges | Exterior Door Hinges |

|---|---|---|

Primary Material | Standard steel, plated brass | Solid brass, stainless steel, bronze |

Security | Removable pins (standard) | Non-removable pins (NRP), security studs |

Corrosion Resistance | Low to Moderate | High (Rust-proof coatings) |

Load Capacity | Light to Medium | Heavy Duty (Ball bearing options) |

Size (Height) | Typically 3.5 inches | Typically 4 inches or larger |

When selecting hardware for the outside of your home, the material isn't just about aesthetics; it is about longevity.

Exterior hinges face rain, humidity, snow, and salt air (if you live near the coast). Standard steel hinges, often used indoors, will rust and seize up quickly when exposed to these elements. Rust not only looks bad but eventually weakens the structural integrity of the hinge, causing the door to sag or fail.

The most common materials for exterior hinges include:

Stainless Steel (Grade 304 or 316): This is the gold standard for exterior durability. It is highly resistant to rust and corrosion. Grade 316 is specifically recommended for coastal areas due to its superior resistance to salt corrosion.

Solid Brass: Brass is naturally rust-resistant. While it may tarnish or develop a patina over time (which some homeowners love for the vintage look), it will not rust away like steel.

Bronze: similar to brass, bronze offers excellent weather resistance and a distinct aesthetic that works well with rustic or traditional architecture.

1

The most distinct difference between interior and exterior hinges is how they handle security.

On an outward-swinging exterior door, the hinge barrel is exposed to the outside. If you used a standard interior hinge with a removable pin, a burglar could simply tap the pin out with a hammer and screwdriver, remove the door from the frame, and walk right in—even if the deadbolt is locked.

Exterior door hinges combat this with specific security mechanisms:

Non-Removable Pins (NRP): These hinges have a set screw inserted into the barrel that is only accessible when the door is open. This prevents the pin from being driven out when the door is closed and locked.\

Security Studs: These hinges feature a small stud on one leaf that fits into a hole on the opposite leaf when the door closes. Even if the pin is cut or removed, the leaves remain locked together, preventing the door from being slid out of the frame.

Yes, size matters when it comes to supporting the weight of an entry door.

Interior doors are often hollow-core and lightweight, usually requiring 3.5-inch hinges. Exterior doors are typically solid wood, fiberglass, or metal, making them significantly heavier. To prevent the door from sagging and dragging against the threshold, exterior hinges are usually 4 inches or 4.5 inches in height.

Furthermore, exterior hinges are thicker (measured in gauge). A standard interior hinge might have a thickness of 0.085 inches, whereas a heavy-duty exterior hinge will often be 0.130 inches or thicker to handle the increased load.

If you have a heavy front door, you have likely noticed that it can require some effort to open. This is where ball bearing hinges make a significant difference.

Standard "plain bearing" hinges rely on the metal barrel grinding against itself to rotate. Over time, the heavy weight of an exterior door wears down this metal, producing fine metal dust (often seen as black residue) and causing the door to squeak or sag.

Ball bearing hinges have lubricated bearings placed between the hinge knuckles. This reduces friction significantly, allowing even heavy doors to swing smoothly and silently. For any solid-core exterior door, upgrading to ball bearing hinges is highly recommended for longevity and ease of use.

While functionality is paramount, you also want your door hardware to look good. Fortunately, high-quality exterior hinges come in a variety of finishes that are treated to withstand the elements.

PVD Finishes: Physical Vapor Deposition (PVD) is a coating process that creates an incredibly durable finish that resists tarnishing, scratching, and corrosion better than standard plating. This is ideal for brass finishes exposed to the sun.

Powder Coating: For black or white hinges, powder coating provides a thick, protective layer that seals the metal against moisture.

When choosing a finish, consider matching your other exterior hardware (locksets, handle sets, and light fixtures) for a cohesive look.

To summarize the options available, here is a breakdown of common hinge types you might encounter when shopping for exterior doors:

Hinge Type | Best Used For | Pros | Cons |

|---|---|---|---|

Butt Hinge (Ball Bearing) | Standard Entry Doors | Smooth operation, long life, supports heavy weight | More expensive than plain bearing |

Spring Hinge | Garage Entry / Fire Doors | Self-closing functionality (often code-required) | Can be difficult to adjust tension |

Invisible/Concealed Hinge | Modern Entryways | Sleek aesthetic, completely hidden when closed | Complex installation, expensive |

Strap Hinge | Gates / Rustic Doors | decorative appeal, high strength | very visible, specific style |

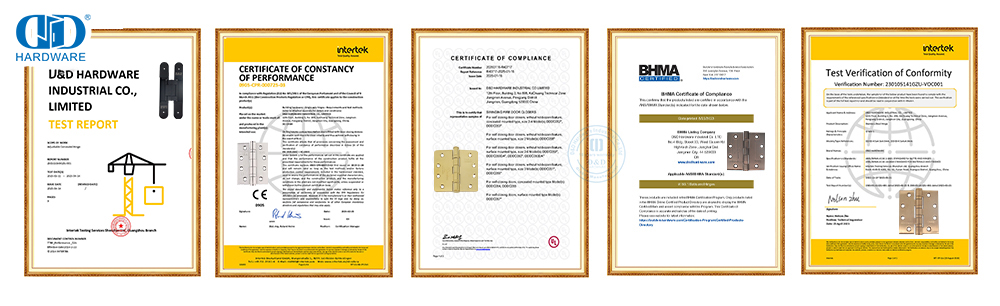

D&D Door Hinge Certification:

️✔ CE Door Hinge - BS EN1935 200,000 cycles test, EN1634 Fire Rated 192mins/260mins, EN1670 Corrosion Resistance 240 hours.

️✔ UL Door Hinge - UL/cUL Listed, UL 10C Fire Rated 3 Hours, File No.R38013

✔ BHMA Door Hinge - ANSI/BHMA 156.1 and ANSI/BHMA 156.18

✔ ANSI Door Hinge - ANSI Grade 1 2,500,000 cycles test, ANSI Grade 2 1,500,000 cycles test

✔ CE Concealed Hinge-BS EN1935 200,000 cycles test, EN1634 Fire Rated 132mins, EN1670 Corrosion Resistance 48 hours.

So, are exterior door hinges different? Absolutely. They are the unsung heroes of your home's security and functionality. By choosing hinges that are specifically designed for the outdoors—featuring non-removable pins, durable materials like stainless steel, and heavy-duty ball bearings—you ensure that your front door remains secure, weather-resistant, and easy to operate for years to come.

If you are unsure about the specific requirements for your project, consulting with a hardware specialist can help you navigate the various grades and certifications available.

Click here for additional details on door hinges.

Now contact us.

Contact information for David Jian

Contact number: 0086-139 2903 7292

Email address: sales@danddhardware.com