Get Famous Branded Quality at Factory Cost

Pls inquire to sales@danddhardware.com

\\: +86 139 2903 7292

When you walk through a commercial building, school, or office, you've likely pushed against a horizontal metal bar to exit through a door. This simple yet ingenious device is called a panic bar, and it serves a critical function in building safety. Understanding how panic bars work can help property managers, business owners, and safety professionals make informed decisions about emergency exit hardware.

Panic bars are designed to allow quick and easy exit during emergencies while maintaining security when needed. They operate on a simple principle: push the bar, and the door opens. But the engineering behind this seemingly straightforward mechanism is more complex than it appears.

Panic bars, also known as crash bars or push bars, are horizontal devices mounted on the interior side of exit doors. They're specifically designed to unlock and open doors when pressure is applied to the bar. The name "panic bar" comes from their primary purpose: allowing people to exit quickly during panic situations without fumbling with traditional door handles or locks.

These devices became essential safety equipment after tragic incidents in the early 1900s where people couldn't escape burning buildings because doors opened inward or had complicated locking mechanisms. The panic bar solved this problem by creating a foolproof exit method that works even when people are stressed, injured, or in darkness.

D&D Panic Exit Hardware Certification:

✔️ Panic Exit Device-BS EN1125 200,000 cycles test, EN1634 Fire Rated 132/240mins, EN1670 Corrosion Resistance 240 hours.

✔️ Fire Exit Hardware- UL 10C Fire Rated 3 Hours, File No.R40486

✔️ Panic Hardware-UL305, File No.SA45817

The fundamental operation of panic bars relies on a spring-loaded mechanism that controls the door's locking system. When someone pushes against the horizontal bar, it compresses internal springs and moves connecting rods or cables. This action retracts the latch bolt from the door frame, allowing the door to swing open.

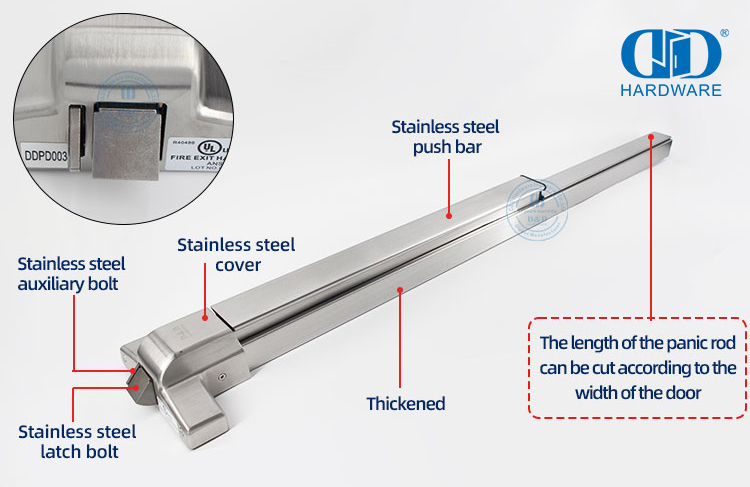

The mechanism typically consists of several key components working together. The horizontal bar, which spans most of the door's width, distributes pressure evenly across the device. Internal springs provide the resistance needed to keep the latch engaged under normal conditions. Connecting rods or cables transfer the force from the bar to the latch mechanism.

Most panic bars require only minimal pressure to activate—usually between 15 to 30 pounds of force applied to the bar. This low threshold ensures that even children, elderly individuals, or injured people can operate the device during emergencies.

Rim-type panic bars are the most common variety found in commercial buildings. The entire mechanism mounts to the interior surface of the door, making installation relatively straightforward. When activated, these bars retract a latch bolt that extends into a strike plate mounted on the door frame.

The advantage of rim-type panic bars lies in their simplicity and reliability. Since all components are visible and accessible, maintenance and troubleshooting become easier. They work well on most door types and can be installed without major modifications to existing doors.

Mortise-type panic bars integrate with a mortise lock body that fits into a pocket cut into the door's edge. This configuration provides a cleaner appearance since less hardware is visible on the door's surface. The panic bar connects to the mortise lock through a series of rods and levers.

These systems offer enhanced security features and can accommodate additional locking points. However, they require more precise installation and may need modifications to existing doors to accommodate the mortise lock body.

Vertical rod panic bars use metal rods that extend vertically from the panic bar to latches at the top and bottom of the door. When the bar is pushed, these rods retract simultaneously, releasing both latches and allowing the door to open.

This design provides superior security since the door is locked at multiple points. Vertical rod systems are particularly effective on double doors or in high-security applications where additional locking points are necessary.

The horizontal bar serves as the primary interface between users and the locking mechanism. It's typically made of steel or aluminum and spans approximately two-thirds of the door's width. The bar must be positioned between 30 and 44 inches from the floor to comply with building codes.

The bar's surface often features a textured or ribbed design to provide better grip, even when wet. Some models include illuminated bars or photoluminescent materials to remain visible during power outages.

Internal springs provide the force needed to keep the latch engaged when the bar isn't being pressed. These springs must be calibrated to provide enough resistance to prevent accidental activation while remaining easy enough to operate during emergencies.

The spring system also ensures that the latch automatically re-engages when pressure is released from the bar. This automatic reset feature maintains security without requiring manual intervention.

The latch assembly controls the actual locking and unlocking of the door. In rim-type systems, this consists of a latch bolt that extends into the strike plate. Mortise systems use a more complex lock body with multiple components.

The latch must be strong enough to withstand significant force while remaining smooth in operation. Most commercial-grade panic bars use hardened steel latches that can withstand hundreds of pounds of pressure.

Rods, cables, or levers connect the horizontal bar to the latch mechanism. These components must transfer force efficiently while maintaining proper alignment over thousands of operation cycles.

The connecting hardware often includes adjustable components that allow technicians to fine-tune the bar's operation during installation or maintenance.

Building codes strictly regulate panic bar installation to ensure proper function during emergencies. The International Building Code (IBC) and local fire codes specify requirements for panic bar placement, operation force, and maintenance.

Panic bars must be installed on doors serving occupancy loads of 50 or more people in most commercial applications. Educational facilities, healthcare facilities, and high-hazard occupancies may have different thresholds.

The bars must be mounted between 30 and 44 inches from the floor, and the activating force cannot exceed 15 pounds. The door must open in the direction of egress travel, and the panic bar must release the latch when pressure is applied.

Regular maintenance ensures panic bars function properly when needed most. Monthly visual inspections should check for obvious damage, proper alignment, and smooth operation. The bar should activate with minimal pressure and return to the locked position when released.

Common issues include sticky or stiff operation, misaligned components, and worn springs. Most problems can be resolved through cleaning, lubrication, or minor adjustments. However, any significant damage or malfunction should be addressed by qualified technicians.

Annual professional inspections are recommended to verify compliance with building codes and manufacturer specifications. These inspections should include testing the activation force, checking all mounting hardware, and verifying proper latch engagement.

Modern panic bars can integrate with building security systems while maintaining their primary emergency exit function. Delayed egress options allow the bar to function normally during emergencies while providing a time delay during non-emergency situations.

Some panic bars include alarm systems that sound when the bar is activated, alerting security personnel to unauthorized exits. These alarms can be integrated with building management systems for centralized monitoring.

Keyed options allow authorized personnel to lock or unlock the panic bar from the exterior side of the door. This feature is useful for controlling access during specific hours while maintaining emergency exit capability.

Selecting appropriate panic bars depends on several factors including door type, security requirements, and building codes. Heavy-duty applications may require vertical rod systems, while standard commercial doors work well with rim-type mechanisms.

Consider the door's material, thickness, and frame type when selecting panic bars. Some systems work better with hollow metal doors, while others are designed for wood or glass doors.

Security needs also influence panic bar selection. High-security applications may benefit from mortise-type systems with multiple locking points, while standard commercial applications can use simpler rim-type devices.

Panic bars represent a critical component of building safety systems. Their simple operation belies sophisticated engineering designed to save lives during emergencies. Understanding how these devices work helps building owners and managers maintain them properly and select appropriate systems for their facilities.

Regular maintenance, proper installation, and compliance with building codes ensure panic bars will function when needed most. By choosing the right type of panic bar system and maintaining it properly, building owners can provide safe egress while meeting security requirements.

Whether you're specifying panic bars for a new construction project or maintaining existing systems, remember that these devices serve as the last line of defense between occupants and potential tragedy. Their reliable operation depends on proper selection, installation, and maintenance—making them worthy of careful attention and respect.

Click here for additional details on panic exit device.

Now contact us.

Contact information for David Jian

Contact number: 0086-139 2903 7292

Email address: sales@danddhardware.com