Get Famous Branded Quality at Factory Cost

Pls inquire to sales@danddhardware.com

\\: +86 139 2903 7292

Every day, you probably turn hundreds of door handles without giving them a second thought. From your bedroom door in the morning to your office entrance, these simple devices grant you access to spaces with just a twist of your wrist. But have you ever wondered about the clever engineering that makes this everyday action possible?

Understanding how a door handle works reveals a fascinating world of mechanical engineering, where springs, latches, and levers work together in perfect harmony. This knowledge can help you make better decisions when choosing door hardware, troubleshoot problems when handles malfunction, and appreciate the ingenuity behind one of humanity's most ubiquitous inventions.

A standard door handle consists of several key components that work together to secure and release your door. The most visible part is the handle or lever itself, which you grip and turn. Connected to this is the spindle, a square metal rod that extends through the door to connect both sides of the handle mechanism.

Inside the door, you'll find the latch assembly, which contains the spring-loaded latch bolt that extends into the door frame to keep the door closed. The strike plate, mounted on the door frame, provides a secure pocket for the latch bolt to rest in when the door is closed.

Supporting these primary components are various springs, screws, and mounting hardware that keep everything aligned and functioning smoothly. The entire system relies on precise tolerances and quality materials to provide years of reliable operation.

Lever-style door handles operate on a simple but effective principle of mechanical leverage. When you press down on the lever, you're applying force at one end of a lever arm that pivots around a central fulcrum point.

This downward motion rotates the spindle, which passes through the door and connects to the latch mechanism on the opposite side. As the spindle turns, it retracts the latch bolt from the strike plate, allowing the door to swing open freely.

The beauty of this system lies in its mechanical advantage. The length of the lever handle amplifies the force you apply, making it easy to retract even a strong spring-loaded latch with minimal effort. This is why lever handles are often preferred in commercial buildings and for accessibility purposes.

Traditional round door knobs work on the same basic principle as lever handles but require a different type of motion. Instead of pressing down, you grip and rotate the entire knob clockwise or counterclockwise.

This rotational motion turns the spindle, which engages with a cam or gear mechanism inside the latch assembly. As you turn the knob, this mechanism retracts the latch bolt, freeing the door to open. The spring inside the latch assembly automatically extends the bolt back into position when you release the knob.

Round knobs require more grip strength and wrist mobility than lever handles, which is why building codes in many areas now require lever handles in public buildings to ensure accessibility for people with limited hand mobility.

The latch assembly represents the most complex part of any door handle system. This mechanism houses the latch bolt, which is the actual component that extends into the door frame to secure the door.

Inside the latch assembly, you'll find a spring that keeps the latch bolt extended by default. When you turn the handle, a cam or angled surface pushes against the latch bolt, compressing the spring and retracting the bolt into the door edge.

Modern latch assemblies also include a deadlatch feature, which prevents the main latch bolt from being pushed back when the door is closed. This small secondary bolt detects when the door is properly closed and locks the main latch in the extended position, providing additional security against forced entry.

Springs play a crucial role in door handle operation, providing the return force that brings handles back to their neutral position after use. In lever handles, a spring-loaded mechanism automatically returns the lever to horizontal after you release it.

These return springs must be carefully calibrated to provide enough force to reliably return the handle while remaining light enough for comfortable operation. Too strong, and the handle becomes difficult to operate; too weak, and the handle may not return properly, leaving the latch partially retracted.

The latch bolt itself also relies on spring pressure to extend into the strike plate. This spring must overcome any friction in the mechanism while providing enough force to keep the door securely closed against wind pressure or settling forces.

Understanding how door handles work helps you diagnose and fix common problems. If a handle feels loose or wobbly, the issue often lies with the mounting screws that secure the handle to the door or with wear in the spindle connection.

When handles don't return to their neutral position properly, the problem typically involves the return spring mechanism. This might require lubrication, adjustment, or replacement of worn spring components.

Doors that don't latch properly may have alignment issues between the latch bolt and strike plate, or the latch assembly itself may need adjustment or replacement. Sometimes, a simple adjustment of the strike plate position can resolve latching problems caused by door settling or thermal expansion.

Contemporary door handle technology has evolved far beyond basic mechanical systems. Smart door handles now incorporate electronic components that can unlock doors via smartphone apps, keypad entry, or proximity sensors.

These advanced systems still rely on the fundamental mechanical principles of traditional handles but add electronic actuators that can retract the latch bolt automatically. The mechanical backup systems ensure that doors remain operable even when electronic components fail.

Some modern handles also incorporate antimicrobial materials or coatings, responding to increased awareness of hygiene concerns in public spaces. These innovations demonstrate how even simple mechanical devices continue to evolve to meet changing needs.

Different door handle mechanisms suit different applications and user needs. Lever handles provide easier operation and better accessibility but may be more prone to accidental activation. Round knobs offer a more traditional aesthetic and may be less likely to catch on clothing or equipment.

Consider the door's intended use, the building's accessibility requirements, and the desired security level when selecting door handle hardware. Heavy-duty applications may require commercial-grade mechanisms with stronger springs and more robust construction.

The finish and material of the door handle also affect both appearance and durability. Solid brass mechanisms typically offer the best longevity, while plated finishes provide more design options at lower cost.

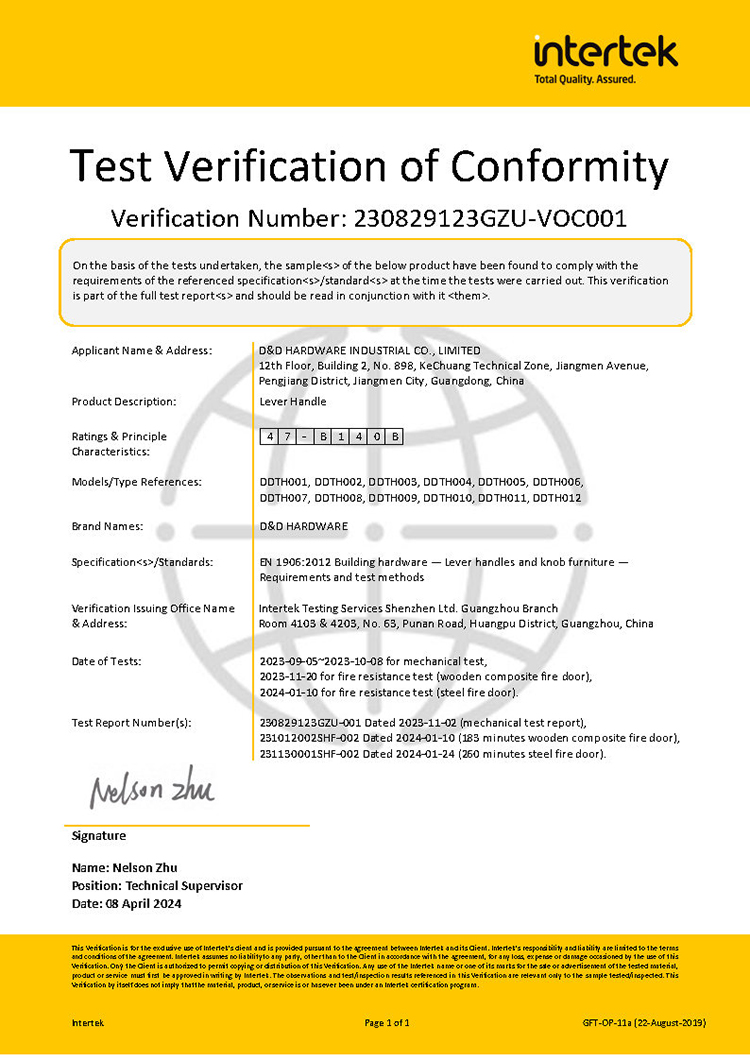

D&D BS EN Door Handle: BS EN1906 300,000 cycles test, EN1634 Fire Rated 183/260mins, EN1670 Corrosion Resistance 240 hours.

The next time you reach for a door handle, take a moment to appreciate the clever engineering that makes this simple action possible. From the mechanical advantage of the lever arm to the precisely calibrated springs that ensure smooth operation, these devices represent centuries of refinement in mechanical design.

Understanding these mechanisms empowers you to make informed decisions about door hardware, maintain your existing handles properly, and troubleshoot problems when they arise. Whether you're a homeowner, building manager, or simply someone who appreciates good design, knowing how door handles work connects you to the ingenious solutions that surround us in everyday life.

Click here for additional details on door handles.

Now contact us.

Contact information for David Jian

Contact number: 0086-139 2903 7292

Email address: sales@danddhardware.com